Personnel Positioning Management System

[ad_1]

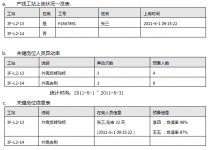

System introduction This system uses UHFRFIDTechnology, real-time reading of the operator information of each station, the back-end system center monitors the job status of each station in real time through the station information and employee information, and evaluates the appropriate operators required by each station through data statistics, Effectively reduce the yield problem of the production line caused by the change and transfer of position operators.

The system is divided into 3 parts:

Personnel information registration: post information includes plant area, floor, line type and station information. Operator information (such as job number) is written into UHF RFID electronic tags and attached to the employee’s factory badge (or use high frequency &UHF RFID dual frequency card)

Data collection and monitoring: Install UHF RFID readers on each station, and associate the reader with the station in the system. When the RFID reader reads the employee’s RFID tag information, it is sent to the system in real time end

System statistical results:

System architecture:

Each UHF reader can be installed with 4 antennas to represent 4 work stations. Each antenna is attached under the electrostatic cloth of the production line, and the antenna board contains a credit card indicator.

UHF readers use TCP/IP network communication (expandable to 2.45G wireless communication).

[ad_2]