Power wireless temperature measurement system based on internet of things

[ad_1]

1. Project overview

Power cables and equipment often cause fires due to overheating in the power industry, resulting in large-area cable burns and equipment damage and forced shutdowns. Production cannot be resumed in a short period of time, resulting in significant economic losses. Through accident analysis, the direct causes of electrical equipment overheating and fires are poor quality of cable intermediate joints, insufficient crimping joints, excessive contact resistance, overheating of cable heads and burning through insulation caused by long-term operation. The quality of the crimping of the cable intermediate joints can only be found in operation. The longer the operation time, the more likely to cause overheating and burn-through accidents. Statistics show that more than 90% of the cable heads made during the infrastructure construction are due to quality in the substation 10 years after the construction. Replace it due to failure.

The specific locations of power station equipment that need to monitor temperature include: conductive busbar connectors, high-voltage switch cabinet contacts, knife switches, dry-type transformers, box-type substations and other equipment surfaces. The characteristics of these temperature measurement locations are:

(1) There are many detection points that need temperature measurement: preliminary statistics of a 220KV substation of various cable joints amount to thousands.

(2) The location of the detection point is very different: some are indoors, some are outdoors; some are in the control cabinet, and some are exposed in the sky.

(3) The voltage of the detection point is as high as hundreds of thousands of volts, and the current is tens of amperes or even hundreds of amperes. There are strong electromagnetic field interference around the equipment.

It can be seen that these detection points cannot use conventional wired methods for temperature detection at all.

Industrial Internet of Things expert Shenyang Institute of Automation, Chinese Academy of Sciences and product promotion practitioner Jin De Chuang Technology used industrial control wireless standard WIA in practical applications to effectively solve this special application problem that has plagued the power industry for a long time.

2. System composition

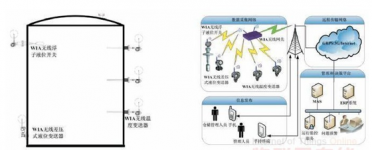

As shown in Figure 1, the basic components of the system include:

(1) Wireless temperature sensor: Collector for short, which is responsible for collecting temperature data at the monitoring point and sending the collected data wirelessly.

(2) Wireless gateway: responsible for collecting the temperature data sent by the wireless temperature sensor, forming a local area network, and uploading the collected data to the temperature measurement management host through the network.

(3) Temperature measurement management machine: Referred to as the host, it is responsible for setting the working parameters of the data receiving and sending terminal, automatically periodically reading the temperature measurement data received from the terminal, and analyzing the data, and finds that the temperature or temperature exceeds the warning If abnormal fluctuation occurs, it will alarm immediately. The temperature measurement data can be stored and recorded in the computer for a long time for query and display at any time.

3. Product features

(1) Contact detection, the data is accurate and reliable.

(2) Wireless temperature monitoring

Wireless communication completely solves the problem of high-voltage isolation and creepage, and does not need to add additional lines in the complex grid environment, which not only facilitates the installation and maintenance of the system, but also reduces the impact on the safe operation of the grid, making the system safe and flexible The performance has been greatly improved.

The wireless communication chooses to work in the 2.4-2.5 GHz working frequency, which is harmless to the human body and has no electromagnetic interference to the surrounding equipment. It complies with FCC standards and national wireless management regulations.

(3) Continuous real-time online monitoring, no time and space blind spots.

Application range:

It is mainly used for contact multi-point online temperature monitoring and early warning in the high-voltage and strong magnetic environment of 220KV and below in the national power system.

Secondly, it is suitable for monitoring and early warning of temperature/liquid level/pressure in national grain depots, cold storages, warehouses, paper mills, coal mines, oil fields, chemicals, metallurgy, wineries and other industries.

[ad_2]