RFID equipment warehouse warehouse management solution

[ad_1]

The public installation warehouse is responsible for the supply of equipment parts, the storage, inspection, packaging and shipping of equipment and equipment and other materials. The entire warehouse consists of four parts: office area, equipment parts area, equipment storage warehouse and consumables warehouse, with a total area of 1,500 square meters per month. The intelligent equipment warehouse warehouse management system is mainly used for the automated management of equipment warehouses and warehouse personnel. It consists of electronic tags, fixed readers, handhelds, management APP and management terminal software installed on the warehouse items.

The main feature of warehouse management is that there are fewer people and more materials and diverse materials. Therefore, different materials need to be managed differently in accordance with the actual situation and management requirements of customers. According to the types of items managed by the warehouse, three management methods are designed in the system, namely, the whole piece management, the box management and the flow management.

Entire piece management requires an electronic label to be attached to each piece of material, which is suitable for the management of high-value materials with a long service life and a relatively small quantity, such as sanitary equipment. If the quantity of material management is huge and the one-time consumption is large, it is not suitable for this type of material. Management method. The advantage of certificate management is that it can automatically manage storage and inventory work, and monitor single items in real time; box management is to pack N materials into a set of sealing management, and electronic labels are issued in units of boxes, which are suitable for volume Small, wide-ranging, and large-volume materials, such as parts and components, and large-volume items are not suitable for this type of management method. The management method of this category can be distinguished from the automatic management of the entire set of materials in and out of the warehouse, the manual management of scattered materials, and the real-time monitoring and management of the entire box of materials; the flow management method is suitable for disposable consumables, low-value but large-quantity items Management is not practical for items with high value for a long time. The management feature is manual operation of materials in and out of the warehouse and manual inventory. Relatively speaking, it is no different from traditional management methods.

The goal of system design is to enable customers to manage warehouse areas, sub-centers, and tertiary station warehouses to achieve real-time, visible, and overall requirements for material management. Through the combination of rfid technology, computer network technology and data analysis technology, the system is based on actual needs, through the development and deployment of software and hardware, to comprehensively improve the digital and intelligent level of warehouse management.

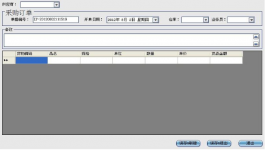

The management software of the system has corresponding modules to maintain and manage the necessary parameters in warehouse management to make it operate well. From the beginning of purchase, there is a corresponding platform for the processing of purchase orders, the maintenance of receipts and return orders. Management module. Delivery, warehousing, audit, and inventory work are also carried out separately. The basic data is maintained uniformly, and the information of customers, suppliers, goods, warehouses, users, departments, warehouses, etc. of the management items are initialized and maintained. For the sales and purchase items that are not within the specified scope, the system separates other items separately. For better management.

Rfid warehouse management system platform module design display diagram:

The design of the system scheme also supports some other functions, such as the identification of tags by the handset to realize quick box searching, automatic setting of inventory tasks and automatic synchronization of inventory results. With the reader/writer equipment installed in the warehouse, the goods with electronic tags can be checked for shipment. If problems are found, the system will prompt an alarm; the goods can also be monitored in real time, and the electronic tags that cannot be read will activate the alarm function. Prompt the relevant personnel to check.

[ad_2]