RFID fire protection material management system solution

[ad_1]

1 Introduction

1.1 Project background

The significance of fire safety is becoming more and more important. In the process of fire fighting and fire fighting, fire equipment is the first safety guarantee and guardian of safety. It is of great significance to ensure the maintenance and management of fire equipment. The use of advanced information technology to strengthen information management capabilities, strengthen the supervision of the inspection process, improve the management level of fire-fighting equipment, and eliminate potential safety hazards.

At present, the management of fire-fighting equipment is still based on manual inspection and manual recording. The inspection records are archived in paper. Unexpected situations found during the inspection, such as the fire extinguisher has been turned on, insufficient weight, insufficient air pressure, etc., are all separately Fill in the form to record, and after recording, it is easy to confuse the fire extinguisher, because the appearance of the fire extinguisher has a certain similarity and is not easy to distinguish. There are more problems in emergencies.

The application of radio frequency identification (RFID), the latest technology product, can fundamentally solve the above-mentioned problems. Based on radio frequency identification (RFID) technology, Hangzhou Dongshi Technology has developed an RFID fire-fighting material management solution based on the actual situation and needs in the management of fire-fighting materials.

1.2 Project goals

Hangzhou Dongshi Technology uses RFID technology to realize the management of the use of fire-fighting materials and provide the accuracy of ERP system data. The main goals are as follows

Improve the timeliness and accuracy of system ERP data

Many aspects of traditional management use manual registration, which is easy to make mistakes; due to manual failure to register in time, the data in the ERP system is not accurate enough.

·real time monitoring

Manage the life cycle of materials and track the use status of equipment.

·Automatically collect data to improve work efficiency

Automatic data collection in the process of entering and leaving the warehouse, improving the efficiency of work.

·Provide leaders with a basis for decision-making analysis

The data can be analyzed online or report can be generated for leadership decision-making and analysis.

2. Overall system design

2.1 System application architecture

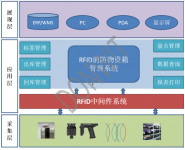

The system application architecture is divided into three logical levels: acquisition layer, application layer, and presentation layer.

·Acquisition layer: readers (handhelds, fixed readers, etc.) read the electronic tag data, and then transmit it to the RFID system through the network and other methods.

·Application layer: Building fire-fighting material management, maintenance, and query applications based on the RFID component system.

· Presentation layer: Users can log in to the system through ERP systems, computers, handhelds, display screens, etc.

2.2 Electronic label scheme

Labels are generally divided into three types according to the classification of materials: anti-metal labels, ordinary label labels, and washing labels.

3. System function design

3.1 Overall process

The RFID fire-fighting material management system mainly controls the material warehouse and the materials on the fire truck. The main process is as follows:

3.2 Label information binding

Before entering the warehouse, a handheld device is used to write data to the RFID tag.

3.3 Warehouse Outbound Management

3.3.1 Inbound management

·Issue the warehousing notice to prepare for warehousing, and the goods pass through the channel

·The reader automatically collects information

·Scanned data is transmitted to the background through the network

·Compare with the warehousing plan data to determine whether the results are consistent,

·If unanimously confirm the completion of storage

·If they are inconsistent, give an alarm, find out the difference between the physical object and the warehousing plan data, confirm it manually, and process the difference result

3.3.2 Outbound management

·Send out the warehouse notice, prepare to go out of the warehouse, and the goods go through the channel

·The reader automatically collects information

·Scanned data is transmitted to the background through the network

·Compare with the outgoing plan data to determine whether the results are consistent,

·If unanimously confirm the delivery is completed

·If they are inconsistent, give an alarm, find out the difference between the physical object and the warehousing plan data, confirm it manually, and process the difference result

3.3.3 Inventory management

The general business process of inventory is as follows:

·The planning department issues an inventory notice and prepares for an inventory

·The warehouse manager receives the order, finds the corresponding location, starts the inventory, turns on the handheld, and scans the product RFID tag information

·Scanned data is automatically transmitted to the ERP system via wireless

·After the ERP system receives the collected information, it compares it with the book data in the system to determine whether the results are consistent.

·If unanimously confirm the inventory is completed

·If they are inconsistent, give an alarm, find out the difference between the physical object and the ERP system data, confirm it manually, and process the difference result

3.4 Real-time monitoring

Install RFID readers and antennas on the fire truck to monitor the firefighting materials in real time. If the firefighting materials are used less during the execution of the task, the system will automatically prompt the alarm to reduce the error rate.

[ad_2]