RFID unattended intelligent weighing software system solution

[ad_1]

one, Overview

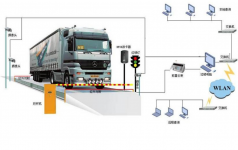

FLYYANGThe unattended intelligent weighing management system is mainly composed of electronic truck scales, computers, printers, video surveillance, radio frequency card reading systems, traffic lights, barriers, and weighing management software. It can be applied to the measurement of goods in mines, ports, garbage disposal and other industries. The system can also be equipped with hardware and software to realize its functions on the basis of the electronic truck scale currently used by the user.The system adopts standardThe WINDOWS window interface and Chinese prompts make the user’s operation simple and intuitive, query and statistical reports are convenient, and truly achieve the measurement work on the go, make the weighing data accurate and reliable, and improve work efficiency and economic benefits. There are two operating modes: manual and automatic weighing. In the unattended state, automatic printing of weighing and scale sheets can be completed without manual intervention, which effectively prevents the occurrence of cheating, and is a beneficial assistant for modern metering.

This system consists of cameras, railing machines, ground sensing coils, red and green signal lights, radio frequency card readers, image capture cards, lighting systems, computers, printers, etc. The car does not need to be supervised during the weighing process, and it is carried out automatically.

2. System composition

“FLYYANGUnattended Intelligent Weighing Software System”, includingRFIDRF card system, barriers, traffic lights,ledLarge-screen display system, video surveillance system, voice intercom system, remote printing system, anti-remote cheating device, etc.; centralized storage at the back-end, and remote output of weighing bills through network printers in each weighing room;RFIDThe radio frequency long-distance card reading and writing system and the road access control system automatically collect the information and data of each transport vehicle, conduct anti-cheating checks, and automatically intercept the vehicle if the weighing process is not completed. The system is also equipped with modules such as order purchasing, sales, weighing, quality inspection, settlement, and financial interface.

3. System features

The system uses microwave radio frequency identification technology, electronic truck scale technology, communication technology, automatic control technology, database technology, computer network technology, software technology, and is a modern intelligent weighing control system.

The main function:

1,It can complete automatic weighing, automatic printing of scales, automatic capture of video recorder images (mainly license plate numbers) and video recording functions without manual intervention (unless the machine or software fails, then manual weighing).

2,During data query, you can click on a record and display the weighing image on the interface at the same time.

3.The card number can be automatically transferred to the corresponding vehicle number, driver, name of goods, supplier and receiver and other information.

4.A large screen display can be installed outside the weighing room to display the weighing weight so that the driver can see the weighing data.

5.You can set the weighing method (one-time or two-time weighing). If it is a one-time weighing method, the system requires the tare weight to be set in advance. When the vehicle number is input, the tare weight corresponding to the vehicle number can be automatically called; if it is the second weighing method, the weighing list will be printed when the second weighing is completed.

6.The system has multi-level operation authority management to prevent the original data from being changed by mistake. Only the person with the operation authority can change some important parameters. Only the super administrator can modify the weighing data.

7. Image capture and video monitoring can be realized: when the car stops on the weighing platform, the system will automatically save the weighing data, and the automatic image capture can be used as a basis for future search. And through the display weighing process for image monitoring.

8, Support manual weighing. When the unattended weighing fails, it can be weighed manually, so as not to affect the weighing of the car.

9,Daily statistics, monthly statistics and statistics for specific time periods can be performed on the weighted data. You can make secondary revisions to the reports and scales, that is, the software supports secondary development.

main feature:

1, Fast information collection speed: The whole system can realize fast weighing, which improves the efficiency of weighing and avoids the phenomenon of queuing overbalance.

2, The operation is simple and convenient: when the vehicle is weighed, there is no need to stop and then come down to submit the bill as before, and the operator in the weighing room does not need to input information into the computer, which saves valuable time for both parties and reduces the number of drivers. The inconvenience of manual input of information by trucks and weighing officers.

3, Blocking the loopholes in human operation: Due to the way of automatically reading data, all over-balanced vehicles are automatically recorded by the computer, eliminating manual intervention, automatically recording data, and automatically verifying and releasing.

4, High security: due to the use of the microwave automatic identification system, the electronic label provides the world’s only unchangeableIDNumber, this fundamentally eliminates the phenomenon of copying, forgery, and cheating.

5, Long use time: The electronic tag adopts passive technology, no maintenance, long service life, and can be used under normal conditions of no damage10year.

Fourth, the basic configuration of the system

1. Weighing host

Recommended storage configuration: Advantech industrial computerP4 2.8GHz/2g/500G/17Inch LCD, if you need to record frequently, it is recommended that the hard disk be larger (such as:1TB); At the same time, it is recommended that the motherboard must be a better choice, so that the system will be more stable.

2. Ground induction coil

The former ground-sensing coil mainly detects whether the tail of the car has passed the ground-sensing coil to ensure that the car is fully driven on the weighing platform. After the car is driven on the weighing platform, put down the railing of the previous railing machine; when the ground coil of the next railing machine is passed after the car is weighed, the railing of the next railing machine is automatically lowered, and the car has been completely driven out of the weighing platform at this time .

3. Intelligent barriers (barriers)

It is required to have a railing machine at the front and back of the weighing platform (the railing machine can be omitted for special requirements) to control the orderly weighing of the vehicle. Some traffic signs can be added to the railing of the railing machine to remind the driver to only drive in from one side, and not to drive in from the other side.

4. Radio frequency reader

The electronic tag reader has a long reading distance (the effective reading distance is greater than7 meters), adapt to moving objects at a fast speed (up to 160 km/h), high readout accuracy (above 99.99%), and strong adaptability to the environment. It is the core component of the intelligent weighing system.

5. RFID radio frequency card (electronic label)

Using readable and writable electronic tags, the electronic tags adopt a passive working mode, which has a long service life and eliminates the problem of electronic tag maintenance for users.The electronic label is affixed to the windshield of the car with a special imported glue. The electronic label contains a fixed, unchangeable, and only one in the world.ID number, with anti-dismantling function, to prevent artificial replacement.

6. Camera

When the car is driven on the weighing platform, the image of the car (mainly the license plate number) is captured and stored in the computer, and the video can be recorded at the same time.The camera is a color camera, clarity480 pixels.

7. Printer

A receipt printer that can automatically cut paper is required.

8. Traffic lights

When there is a car on the scale, that is, when the rail of the previous barrier is down, a red light is displayed; when there is no car, that is, when the barrier of the previous barrier is raised, a green light is displayed.

9. Infrared on the radio

Install a pair of infrared beamers at both ends of the weighing body, and the infrared device is connected to the switch via a signal lineIO card. When the beam is blocked, the infrared beamer will send the signal to the switch IO card, and the platform weighing software extracts the signal from the switch input card. When the alarm signal is detected, the system prohibits the weighing system data saving and the weighing process is terminated. .

5. Work flow:

1. The system administrator sends the radio frequency card to the driver, which has entered the car number and other content, and the driver can stick the card on the front windshield of the car. When it is a few meters away from the weighing platform, the card reader detects the arrival of the vehicle, and when it is determined that there is no vehicle weighing on the weighing platform, the imported railing machine is opened to let the vehicle pass and the weighing platform is turned on;

2. After the vehicle is stopped, the camera will automatically take a photo of the vehicle number and save it in the computer;

3. The computer reads and saves the weighing data of the instrument;

4. After the weighing is completed, the exit railing machine is lifted to let the car drive out of the weighing platform;

5. Place a scale printer at the exit, and the driver will tear off the printed scale and leave;

6. The system can be connected to the Internet to transmit data and image data over a long distance;

[ad_2]