E-commerce logistics center order electronic label picking operation plan

[ad_1]

1. Order fruit picking mode

The order picking mode is the most primitive order operation mode. An order is completed independently by an operator. The picking receipt can be used during the picking process, and the handheld terminal RF can also be used to improve the accuracy of picking. The order picking mode is widely used in traditional industries. As the average daily order scale of the e-commerce industry is much larger than that of the traditional industry, unless the warehouse area is small and the product variety is small, this mode of operation is generally not recommended, but it can be used for emergency Picking operations for orders and special-shaped goods orders.

2. Order sorting and sorting mode

Statistics show that in the complete order picking operation mode, the picking operators in the e-commerce warehouse spend more than 70% of their time on repeated walking. We have counted the walking time of pickers in a pioneering company in the e-commerce industry, and found that on average, each picker has to walk about 20 to 25 kilometers a day. This is a very direct cause of low picking efficiency.

The sorting and sorting operation mode effectively solves this problem. In this operation mode, a certain number of orders are merged first. The specific combined quantity depends on the physical properties of the product and the volume of the picking vehicle. It can be 4 orders per car, 20 orders per car, and even 64 orders per car.

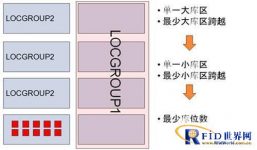

Even without any combination optimization of orders, this operation mode can effectively reduce the ineffective walking distance of pickers and greatly improve the efficiency of picking operations. Assuming that the WMS system is used to optimize the combination of orders, the efficiency will be even greater. The principle of combinatorial optimization is mainly based on the three-level partition of the warehouse. The former operation scope based entirely on the entire warehouse area is converted into a “community” operation mode. The orders in the order pool are analyzed through the system, and the Recursive combination of orders in a “community” or even a “location” minimizes the work area and picking path covered by order picking within a wave.

The use of handheld terminal RF or vehicle-mounted terminal VC is very important to improve the accuracy of sorting and sorting. The functions of the terminal include:

1. Instruct the pickers to work paths

2. Prompt the quantity of combined picking and the quantity of each order that needs to be divided

3. Scan the location to verify the correctness of the picking. When there are not many trolleys, you can use the graphical display mode (left picture) to enable the operator to directly correspond to the position of the trolley. In the case of more trolleys with more cargo spaces, the method of using the list (pictured on the right) will be more efficient.

After a wave of picking operation is over, the packer can directly review and pack according to the order, without the need for secondary sorting. The operation mode of sorting and sorting is very suitable for e-commerce companies operating small commodities such as clothing, cosmetics, and 3C products. A domestic 3C e-commerce company, through the application of this operation mode, the daily average picking ability of pickers has increased to 1,000 to 1,200 orders per day.

3. Single product operation mode

In e-commerce companies, single product orders will account for a considerable proportion. The so-called single product order means that the customer’s order only ordered a single product (the quantity may be one or more). For single product orders, it is recommended to separate the picking and review packaging operations from other types of orders. The WMS system will screen the orders in the order pool and accumulate the number of single products to complete the combined picking operation with the highest efficiency. At the recheck packing station, after scanning the product barcode, the WMS system will automatically match an order and then print the face slip. If the face slip is printed in advance, the order number barcode will be printed on the face slip. When rechecking, just scan the order number barcode. You can complete the review and packaging of the single product according to the prompts of the system.

4. Electronic tag assisted picking mode

In order to improve the efficiency of picking, the G-PICK electronic picking label (Put-To-Light) technology is generally used. When the product barcode is scanned, the light corresponding to the goods compartment (order) is lit to show the quantity to be planted. Operators can directly and efficiently complete the sowing operation of the goods.

E-commerce logistics centers began to pay more and more attention to this automated cargo operation mode.However, it has not yet reached the level of popularization. There are many reasons.electronic labelThere are not many suppliers, and the quality is also uneven. In addition, some foreign manufacturers have higher prices, which are more difficult to bear in the low-profit e-commerce industry. At present, the most promising one is the G-PICK electronic tag for picking independently developed by China Qualcomm. Unique 2.4-inch TFT full-color screen display, support for large digital display from 16 to 128 points, multi-template display interface, can display specifications, batch numbers, barcodes, etc., which can well meet the application of sorting of different items in the e-commerce industry .

(1) Pickup picking

Pick-up picking is mainly used in the occasions where order picking is taken. According to the display of light numbers and numbers, it can quickly and simply guide pickers to find the correct storage location. In principle, one electronic label corresponds to one storage item. In addition, the light signal can not only guide the pickers to the correct position, but also display the exact number of picking items. When the picking is completed, it is also required to press the confirm button to confirm.

(2) Seed picking

The seeding type is usually used in situations where batch picking is handled, and its function is just the opposite of the picking type. An electronic label corresponds to a store or an order. When the goods of the order are aggregated into the storage area in batches, the seeding system is used. The picker reads the product information through the scanner of the products after the batch is collected, and the corresponding electronic label will display the quantity. The picker picks the same number of products and assigns them to the corresponding storage location of the label, and then extinguishes the label. Finish picking.

About Qualcomm:

Qualcomm is a world-renowned smart brand and smart device and solution expert, focusing on the system development and application of “smart devices and solutions” in the field of business intelligence. Relying on 20 years of industry experience and deep IT technology reserves, adhering to the business philosophy of “change life with intelligence, and inherit civilization with technology”, we continue to promote the development of people’s material life and spiritual civilization.

[ad_2]