RFID anti-counterfeiting supervision and management plan

[ad_1]

1. System Overview

1.1. System background

In today’s society, counterfeit goods have become a worldwide problem. Driven by interests, counterfeit and inferior products are increasingly rampant in the market, especially for commodities that are closely related to our lives, such as tobacco, alcohol and clothing. First, it has brought great threats to people’s lives and even life safety, and also caused huge losses to enterprises. At present, various commodity anti-counterfeiting technologies use paper-based materials, which are not unique, and the difficulty of counterfeiting is not high. Counterfeiters often master the anti-counterfeiting technology quickly, and even counterfeit it with technical developers who lack self-discipline, causing headaches for various commodity manufacturers Endless.

1.2. Status Quo and Analysis

Based on the shortcomings of the existing anti-counterfeiting technology, our company recommends the use of RFID technology to realize the anti-counterfeiting of goods. The advantage of RFID product anti-counterfeiting is that each label has a unique ID number, which cannot be modified or counterfeited. RFID technology can prevent major products from mechanical abrasion and contamination; the reader has a physical interface that is not directly open to the end user to ensure its own security; in terms of data security, in addition to the password protection of the label, the data Some algorithms can be used to achieve security management; there is a mutual authentication process between the reader and the tag; the data storage capacity is large, the content can be erased multiple times, and a logistics and supply chain management system based on RFID technology can also be established. It can record the whole process of each product’s production, warehousing, sales and delivery, and can automatically count the output, sales and other information, while achieving the anti-counterfeiting effect, it can achieve multiple goals and realize the informatization of management. The use of RFID product anti-counterfeiting technology can prevent counterfeit products from flowing into the sales market, control product quality, supervise and manage sales personnel, formulate reasonable service strategies, strengthen market control and management, guide enterprise product design and positioning, and improve the timeliness of business decision-making.

In the whole process of commodity circulation, merchants can use RFID handsets to conduct dynamic collection, real-time feedback, comprehensive processing, real-time recording, and analysis of commodity information. Effectively avoid the disadvantages of scattered, chaotic, and irregular products, better manage product sales and after-sales service, reduce manual errors, and prevent the mixing of fake and inferior products.

2. System introduction

2.1. System principle

The ID number of the RFID tag is unique in the world and can be used to uniquely identify the product. In addition, RFID tags can read and write data. According to the principle of data encryption algorithm, the system can encrypt the product code, production batch number, expiration date and other variable data to generate a globally unique digital supervision code, and write the code into the electronic Label, and store the digital supervision code containing the ID number into the central database via the local area network or the wide area network.

In the process of commodity delivery, warehousing, flow and sales, merchants and customers can identify the product label information through RFID readers, and compare the information with the information on the Web server to determine the authenticity of the product.

In practical applications, criminals may recycle the RFID tags on the packaging to counterfeit products. Therefore, the RFID tags are required to be destructive, and once they are removed, they will be scrapped, avoiding label recycling and reuse.

2.2. System structure

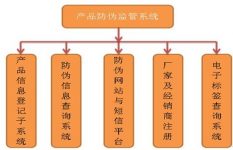

The product anti-counterfeiting supervision platform includes the following subsystems: product information registration subsystem, anti-counterfeiting information query system, anti-counterfeiting website and SMS platform, manufacturer and distributor registration, and electronic label query system.

Figure 1: System structure diagram

Product Information Registration Subsystem

The product information registration subsystem is composed of RFID read-write equipment and corresponding computer software and hardware. It is used for product information registration. The product’s anti-counterfeiting code is encrypted and written into the electronic label. At the same time, the label is recorded in the local data cache. Establish a synchronization mechanism between the cache and the back-end database system.

Anti-counterfeiting information query system

The anti-counterfeiting query subsystem is used in the sales link, and is divided into two types: fixed query machine and hand-held machine. The fixed inquiry machine is used in large shopping malls, supermarkets or businesses that can access the Internet through a computer. You only need to place the product with an RFID tag on the inquiry table. The system automatically recognizes the tag number and anti-counterfeiting code, and retrieves the manufacturer, product, production date, Information about the production process.

Handhelds are generally used for merchants’ purchase inspections, and are connected to anti-counterfeiting databases through GPRS for retrieval. At the same time, the back-end database system automatically records the inquired label, location, inquiry machine number and other information for tracking the entire logistics link.

Anti-counterfeiting website and SMS platform

After consumers obtain the tag ID number and anti-counterfeiting code, they will verify the authenticity of the anti-counterfeit code via SMS or website, and inquire about the authenticity of the product and product-related information.

Manufacturer and distributor registration

In order to ensure the authenticity of anti-counterfeiting information and the quality of products that have passed anti-counterfeiting certification, manufacturers and products entering the anti-counterfeiting system should first be certified.The electronic label is registered by the anti-counterfeiting traceability platform and the electronic label ID number is issued. Only the registered label enters the production and circulation link to prevent the inflow of illegal channels

Electronic label query system

The product manufacturer enters the product information corresponding to the label into the system and saves it. The content mainly includes the basic information of the product, such as: origin, manufacturer, brand, production date, variety, grade, etc., to meet the needs of general users to inquire about anti-counterfeiting information .

2.3. System topology diagram

Figure 2: System topology diagram

2.4. System flow

2.4.1. Application process

The use of RFID technology will optimize the production, circulation, and sales of the entire product. On the one hand, it can obtain accurate information flow in real time, improve the monitoring in the logistics process, reduce unnecessary links and losses in the logistics process, and reduce Safety inventory and operating capital in all links of the supply chain; on the other hand, through the monitoring of the final sales realization, the consumer’s consumption preferences are reported in a timely manner to help merchants adjust and optimize the product structure to obtain higher customers Satisfaction and loyalty. The commodity anti-counterfeiting system runs through the whole process of commodity production, sales and circulation, data collection and information processing. The whole link is meticulous, which can effectively realize anti-counterfeiting and curb the inflow of counterfeit goods into the market. The schematic diagram of the specific system scheme is shown in the figure:

Figure 3: Application process

2.4.2. Work flow

Preparation of anti-counterfeiting data and labeling

The product code, production batch number, expiration date and other variable data are encrypted and processed to generate a globally unique digital supervision code, which is written into the electronic label.

In the production process, the electronic label is combined with the original product identification, attached to the product, and then packed into the packaging box. The electronic label is an EPC label with identification information printed on the surface. Labels can be pasted manually or mechanically. In order to prevent labels from being reused, tamper-evident labels can be used. Once they are disassembled, they will be scrapped.

[ad_2]