Ground magnetic equipment for automatic phase passing device of electric locomotive

[ad_1]

I. Overview

Shenzhen Fengteruida Industrial Co., Ltd.’s electric locomotive automatic phase passing ground magnetic equipment is a ground magnetic equipment of the vehicle automatic phase passing control system based on maintenance-free ground positioning technology. The locomotive determines the relative position of the locomotive and the phase splitting point by sensing the ground positioning signal. The ground positioning and the locomotive sensing signal are respectively buried and received obliquely symmetrically to ensure the safety and reliability of the automatic phase passing.

2. Main performance

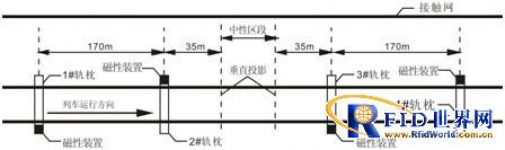

When the electric locomotive passes through, it will send out the corresponding signal to the locomotive, and automatically complete the power-off of the electric locomotive and the excess phase through the on-board sensor receiver and the excess phase control device. The automatic phase-passing ground magnet induction device is a permanent magnet embedded in the sleeper. It has the characteristics of high temperature resistance, corrosion resistance, no loss, no damage, etc., suitable for installation in the outdoor automatic phase-passing ground device for ballasted tracks and ballastless tracks There are two types of tracks. The ballast track is a concrete sleeper with a magnetic signal device at one end—signal sleeper; the ballastless track installation is to install permanent magnets in a special box. The signal device will send out corresponding signals to the locomotive when the locomotive passes. Each split point needs to install four signal sleepers (magnetic mounting device). Counting from the direction of the incoming traffic, the first signal sleeper (magnetic device) is an advance notice (main break), the second signal sleeper (magnetic device) is forced break (main break), and the third signal sleeper (magnetic device) In order to restore (main off), the fourth signal sleeper (magnetic device) is a warning for standby recovery or when the locomotive runs in the reverse direction (main off). The 4 sleepers (magnetic devices) are called No. 1, No. 2, No. 3 and No. 4 sleepers in sequence.

The schematic diagram of the signal sleeper (magnetic device) and the position of the magnetic end is shown in the figure below:

3. Composition and appearance of ground magnetic equipment

The ballast track ground magnetic equipment is a permanent magnet embedded in the sleeper, and the ballast track is a specially assembled magnetic device, which has the characteristics of high temperature resistance, corrosion resistance, no loss, no damage, etc., suitable for installation outdoors.

Magnetic sleeper (applicable to ballast track)

(1) Signal sleeper

Reinforced concrete sleepers with special special moulds have excellent characteristics such as long service life, high stability, and small maintenance workload.

(2) Magnetic induction device

The magnet induction device manufactured by a special process has excellent characteristics such as stable magnetic field, anti-vibration, not easy to attenuate, high temperature resistance, and corrosion resistance. The magnetic steel body is welded and fixed at the bottom of the rail by a penetrating steel column, and a special filler is then poured to bond the magnetic steel body and the pillow body.

(3) Ballastless equipment protective cover and other accessories

The ballastless equipment uses a magnet induction device manufactured by a special process. The bottom is welded to the steel bottom plate as a whole, and the cover is bonded and filled with the magnet. The magnet body uses a sintered matrix magnetic group, which is welded to the high-strength steel bottom plate, and is filled with special fillers. The magnetic steel body and the stainless steel protective cover are fully bonded. Impact resistance, vibration resistance, wear resistance and corrosion resistance. Each magnetic device is equipped with four special stainless steel expansion bolts, the size of the bolts is M10mm╳100mm.

Each device has a clear and obvious nameplate identification, and the identification content is complete: brand, model, manufacturer, production year, serial number, etc.

4. Working environment:

Applicable speed range: 10~250km/h.

It is suitable for single-phase 50Hz, 25kV AC electrified railway catenary project.

Ambient temperature: -40℃~80℃

Wind deviation design wind speed: better than 30m/s

Structure wind speed: 40m/s.

Ice coating thickness (support cable/contact wire): 10 mm/5 mm

Thunder and Lightning Day: Minefield

Altitude: ≤ 5600m

Earthquake intensity: ≤Ⅷ degree

Five, daily maintenance

Road inspection:

Patrolmen should pay attention to the integrity of the signal sleeper during routine inspections. For example, if the magnet part is found to be stolen or scratched by the product hanging from the train, it is at the shoulder of the sleeper between the magnet and the fastener. In the event of abnormal conditions such as cracks, looseness, etc., it should be reported to the superior for inspection and treatment in time, and replaced if necessary.

Need to replace or repair:

The magnet is stolen, cracked, damaged, loosened, and the protective cover is tilted, etc.;

Cracks appear on the shoulder of the sleeper;

The magnetic field strength of ground magnetic equipment is lower than the lowest effective value;

When the degree of wear of the protective cover affects safe use, it should be replaced;

Avoid moving and removing signal sleepers at will:

In order to ensure the normal use of the vehicle-mounted automatic phase separation system, the laying position of the signal sleeper is closely related to the catenary phase separation area, so it is not allowed to move or even remove the signal sleeper without authorization.

If the signal sleeper has to be changed due to special needs such as emergency rescue or restoration of the disaster-stricken area, it should be clearly marked at the corresponding position, and reported to the work depot in time to notify the neighboring locomotive depot to notify the driver to manually pass the phased section. After the disaster factor is eliminated and the normal line is restored, the missing signal sleepers should be filled as soon as possible in the original position in order to restore the ground positioning function of the ground magnetic equipment in the phase separation zone.

Shenzhen Fengtai Ruida Co., Ltd. is a high-tech enterprise and dual software enterprise specializing in microwave radio frequency identification, communication, automatic control, computer information system integration, and software and hardware R&D, manufacturing, sales and services. The following products are now developed: train temporary speed limit early warning and control system, electric locomotive automatic phase separation device, locomotive driver video monitoring and recording device, student safety management system, health information network citizen health card system, and medical self-service platform.

[ad_2]