Long-distance identification of inland watercraft (available with Shanghai Xiupai products)

[ad_1]

Challenges and needs

my country has entered a period of building a well-off society in an all-round way. Building a “harmonious society” has become an important goal of my country’s social and economic development at this stage. How to better strengthen the construction of water transportation supervision facilities to ensure the safety of people’s lives and property and protect the environment? Ensuring the sustainable development of the economy has become the top priority of the port and shipping department. In recent years, as land transportation has gradually shown a bottleneck in logistics volume, improving water transportation efficiency and improving the supervision environment of water transportation have gradually become the development strategies of cities along the river. In the traditional “golden waterways” of the Yangtze River Delta and areas along the canals, major cities are formulating ambitious plans for “Strong City of Water Transport” and “Digital Port and Shipping” to give full play to their advantages in inland waterway and reduce logistics and transportation costs. Improve the comprehensive competitiveness of the economy and society in order to further support the rapid development of economic construction.

In the actual business environment, information technology has been widely and far-reaching applications. Each inland port and shipping city has invested a lot of manpower and material resources to accelerate the pace of information network construction and technology investment, such as establishing and improving the ship center database of the entire shipping area, and implementing annual ship review, entry and exit visas, and collection of fees based on the port and shipping management business. , On-site supervision, comprehensive utilization of information and other business information, network dynamic management. These system applications relying on advanced information technology have realized non-stop navigation inspections, broke the traditional mode of “territorial management”, and laid a solid foundation for building a “digital port and shipping”. However, the on-site supervision modules of these systems are still used The collection method of manual entry of ship name and ship number. If the ship’s name and ship number are covered, the ship cannot be seen clearly at night, the flow of ships is too large, and the operator is sleepy, this may cause the ship’s name and ship number to be unable to realize automatic identification, which becomes the biggest bottleneck in creating a “digital port and shipping”. So, is there an economical and practical way to solve the automatic identification of ship numbers? Yes, this is a new technology that has matured in recent years, namely Radio Frequency Identification (RFID).

RFID is an automatic identification technology that originated in the 1950s. It uses radio frequency for non-contact communication to exchange data for identification purposes. A typical RFID application system usually consists of an electronic tag that identifies a specific target object, a reader that receives the electronic tag signal, and application software. Compared with traditional magnetic cards and contact IC cards, RFID technology does not require human intervention when completing the identification work. It is suitable for automatic operation of the system and is not easily damaged. It can identify high-speed moving objects and can identify multiple radio frequency cards at the same time, which is fast and convenient. . Electronic tags can adopt a special packaging method to effectively resist corrosion and invasion of harsh environments such as oil stains and dust pollution.

Radio frequency identification systems can be divided into active and passive according to the power supply mode of electronic tags. The working energy required by the passive tag needs to be obtained from the radio frequency beam emitted by the reader, and provided after rectification and storage. The cost is relatively low, but the radio frequency power is relatively large. The active tag itself has a miniature battery. Because it does not require radio frequency power supply, its identification distance is longer, the reader needs less power, and it has the advantages of stable reading and writing, good anti-collision performance, and large amount of information carried. Both are critical performance requirements in ship identification applications.

application solution

Relying on its solid foundation in active RFID technology, Shanghai Supai Electronic Technology Co., Ltd. has launched a series of electronic tags and active products, which are warmly welcomed by the market. Its stable product performance, strong technical support force and perfect after-sales service The system has won countless loyal customers in various RFID application fields for Shanghai Showpad. It has also contributed to the extremely challenging highway non-stop toll application and the ship identification application under severe conditions.

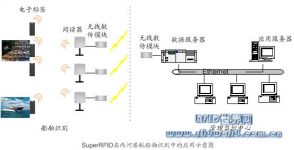

As shown in the above figure, active electronic tags are installed on ships entering and leaving the navigation area (to prevent embezzlement, special measures can be taken to achieve the anti-disassembly requirements), and individual information or cargo information related to the ship can be stored in the tags. A long-distance reader is installed on the channel, which is connected to the background through a standard serial port RS232/485 interface, and a wireless data transmission module (GPRS/CDMA) can be linked to the background application system to maintain real-time communication with the background application system in areas that are not easy to wire. In this way, when a ship with an electronic tag passes through the channel, it will be recognized and read by the reader within a range of up to 80 meters. A port supervisory management boat can be arranged downstream of the reader installation location. The computer in the port supervisory management boat maintains an online status with the central database through the wireless Internet access system. The on-site supervisory personnel can perform targeted reloading at any time through the displayed results. Non-stop inspection of ships. If it is a problematic ship with an incomplete license or an expired license, the harbor supervision management boat can quickly get out of the boat for inspection. Of course, the port supervision and management boat can also use a portable mobile reader to achieve the audit management goals for all related ships. The following are the specific details of some application schemes:

First, the installation of the reader. The reader should be installed in an appropriate position to ensure that it can read 100% of the electronic tags of all ships passing through the channel. The deployment strategy of installing on both sides of the channel and on the bridge across the river can be adopted: the height of the bridge is generally no more than 30 meters, so install the reader on the underside of the bridge and try to cover most of the area under the bridge. At this time, no matter where the ship passes through any position on the underside of the bridge, the distance between the RF antenna and the ship will not exceed 30 meters, thus ensuring the effective reading and writing of the electronic tag by the reader, and the correct and effective ship name and ship number. Recognition.

Second, the installation of the electronic tag card on the ship. From the perspective of system stability, it is more appropriate to use active electronic tags. Electronic tags are generally installed in areas that are seldom touched by the crew and have little interference. For example, the upper side of the ship’s steering window is the best place to install it. The active electronic tag has a high level of protection, the shell is firm, can effectively resist rain and is easy to install, and has strong anti-pollution ability. It can be used reliably even if it is directly installed on some transport tugs without driving windows.

Third, use policy means to ensure the issuance of electronic labels. The application of RFID technology in inland waterway management is still relatively small, and ship owners may have various doubts about the operation and economics of the technology, which leads to a situation of non-cooperation. The main problem is that the shipowner thinks that the electronic tag has been monitored by the port and shipping management department and does not cooperate. On the one hand, the port and shipping management department should allow ship owners to accept it through publicity, and on the other hand, it should formulate corresponding policies to restrict non-cooperative ship owners to ensure the smooth issuance of electronic tags. For ships of foreign port nationality, electronic tags can be issued when entering and leaving the port to ensure that all ships in the navigation area can achieve on-site management through radio frequency identification technology.

Program features

1. Large flow: extremely high anti-collision performance, adopting multiple anti-collision schemes, supporting simultaneous reading of more than 200 tags;

2. It supports high-speed mobile reading, and the moving speed of the identification card can reach more than 200 km/h.

3. High reliability, working temperature -40℃~85℃, waterproof and shockproof, meeting the application of industrial-grade environment.

4. High anti-interference: There are no special requirements for various interference sources on site, and the installation is convenient and simple.

5. There is no need to apply and pay for the ISM microwave frequency band that is open worldwide.

6. Ultra-low power consumption: It is safe for the human body and has no health damage.

7. Ship passing records. Every time a ship passes a monitoring point, it will be automatically 100% recorded in the central database.

8. Non-stop ship inspection. The port supervision management boat can realize non-stop inspection of sailing ships, which greatly facilitates supervision work.

9. Management of gate fees. For ship locks that charge gate fees based on voyages, using the identification system combined with the charging system can realize non-stop ship charges for credited ship owners, effectively increasing the lock passing rate and reducing the chance of blocked voyages.

10. Toll management of the “Four Self” channel. The installation of the identification system at the entrance of the “Four Self” Channel can effectively record the ships entering the “Four Self” Channel, and combined with the ship’s credit account, it can realize fee deduction and payment.

11. Anti-counterfeiting of ship certificates. In order to evade punishment and payment of fees, falsification of ship certificate data, ship name and ship number is rampant. After adopting RFID technology, due to the global uniqueness of the electronic tag ID number and the anti-disassembly measures of the electronic tag, such problems can be completely eliminated.

12. Management of problematic ships. Since the identification control computer queries the central database for ship information in real time, there will be no way for the ship to hide from problems such as illegal ships, expired annual inspections, and expired certificates.

13. Traffic and transportation volume statistics. It can accurately and automatically count the traffic and freight volume of passing ships.

product description

1. Active proximity card SP-TGS-300

Its main technical performance is as follows:

Recognition distance: up to 80 meters (with SP-RGS-300, in the air)

Working frequency band: 2.4-2.48G

Receiving sensitivity: -80 dbm ~ -90 dbm

Storage space: standard 97 bytes, expandable

Expected battery life: 6 years, automatic alarm when battery power is too low

Power-down storage period: more than 10 years

ID number: 64 bit

Working temperature: -40℃ ~ +80℃

Storage temperature: -60℃ ~ +85℃

Anti-electromagnetic interference: 10V/m 0.1~1000MHz AM electromagnetic wave

Vibration: 10~2000Hz 15g three axes

Free fall: 1500mm concrete floor, twice on each side

2. Reader (card reader) SP-RFS-300 series

The main technical performance is as follows:

Recognition speed: 100 tags/sec (ID number only)

Anti-collision processing: 200 tags read at the same time

Recognition distance: up to 80 meters (with SP-TGS series tags, in the air)

Working frequency band: 2.4-2.48G

Output power: ≤3 dBm (adjustable by software)

Microwave communication error detection: CRC16 cyclic redundancy check

Antenna polarization: directional/omnidirectional

Standards/Certifications: CE; FCC; ISO9001

Power supply: 6~12V DC (MAX 30mA)

Communication interface: RS232/485/Wigan Baud rate: 4800~115200

Working temperature: -40℃ ~ +80℃

Storage temperature: -60℃ ~ +80℃

Anti-electromagnetic interference: 10V/m 0.1~1000MHz AM electromagnetic wave

Reliability: MTBF ≥ 70000 hours

3. Handheld reader SP-RCF-100 series

The main technical performance is as follows:

Recognition speed: 100 tags/sec (ID number only)

Anti-collision processing: 200 tags read at the same time

Recognition distance: up to 30 meters (with SP-TGS series tags, in the air)

Working frequency band: 2.4-2.48G

Output power: ≤3 dBm (software adjustable)

Microwave communication error detection: CRC16 cyclic redundancy check

Antenna polarization: circular polarization

Standards/Certifications: CE; FCC; ISO9001

Power supply: PDA power supply

Communication interface: CF Baud rate: 19200

Working temperature: -40℃ ~ +80℃

Storage temperature: -60℃ ~ +80℃

Anti-electromagnetic interference: 10V/m 0.1~1000MHz AM electromagnetic wave

Reliability: MTBF ≥ 70000 hours

[ad_2]