Logistics warehousing barcode management solution

[ad_1]

System Overview

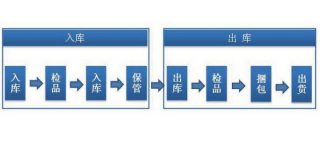

It is suitable for warehouse entry and exit management and shelf position management.

Knowing the correct inventory is very important to the warehouse management when shipping or ordering, and barcode scanning can be used to inspect products to improve inventory accuracy.

Pack the actual logistics operations and unite with the system vendors to better assist the logistics site.

Advantage

Improve the efficiency of warehouse operations

Scanning barcodes such as JANITF on the product, even beginners can operate correctly.

Improve the accuracy of inventory management

Grasp the actual performance data of inbound and outbound to improve the accuracy of inventory management. In addition, we can also provide management of the inventory status of different warehouses.

Build an independent storage system

Connect the data with the backbone system to build an independent warehouse system. The actual operation is also easy to input data by connecting with the backbone system.

Improve site operability

Use wireless handheld terminals to confirm goods anytime and anywhere, and use mobile printers to print labels immediately on site.

Import effect

Inbound inspection

Eliminates the step of visually checking the order to verify the product. Eliminate mistakes in goods in storage to achieve correct merchandise management.

Effectively use the actual storage performance data to reduce the work of entering order data.

Goods placement instructions

Ensure the correct placement of the goods according to the position indication label when entering the warehouse, which greatly shortens the time from entering the warehouse to placing the goods on the shelf.

Sorting

Eliminate repetitive work caused by sorting errors without sorting the list of goods, and realize paperless operations.

In addition to the tension and fatigue caused by visual inspection, even beginners can quickly and correctly grasp the items by scanning the barcodes of the items.

Shipping label (shipping party, packing details)

The inspection results are clear at a glance, which improves customer satisfaction and prevents the wrong goods from being picked up. On-site printing does not affect work efficiency at all.

Cargo location management

When the product is changed, you can simply log in and change the information according to the barcode of the shelf and the product. It also eliminates errors and troubles that may occur when shelf product data is manually entered into the computer.

related software

Label Gallery 3

[ad_2]