RFID appliance tracking management system

[ad_1]

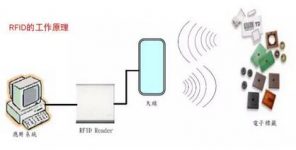

1 Basic understanding of RFID

RFID technology is a non-contact automatic identification technology, which automatically recognizes the target object and obtains related data through radio frequency signals. The identification work does not require manual intervention and can work in various harsh environments.

RFID technology can identify high-speed moving objects and can identify multiple tags at the same time, and the operation is quick and convenient. It has significant advantages such as non-contact, high accuracy, anti-interference, fast speed, and strong adaptability to the environment. It can be widely used in fields such as production management, logistics management, transportation, medical and health, commodity anti-counterfeiting, asset management, and national defense and military.

1. The characteristics of RFID:

Reading data without directional restrictions;

Long recognition distance;

Fast recognition speed;

High recognition accuracy;

Reading/writing ability, large amount of memory;

High security;

long life;

Good label penetration;

Can work in harsh environments.

2. Advantages of RFID

RFID technology is a new automatic identification technology that reforms product production, inventory, logistics distribution and product sales management mode after barcode technology. It is the extension and expansion of barcode technology application.

2 RFID management requirements

1. Business description

The main car factory’s parts need various appliances during the conversion process, and the management of general appliances is managed by a third-party company. The third-party management company is not only responsible for the assets of the OEM, but also to ensure the supply of equipment.

2. Management confusion

The appliance is used by the main depot and outsourcing factory, but the management is managed by a third-party company, and the management process relies on manual management. Due to the large number of appliances and frequent material turnover, information statistics are difficult and the information is not transparent, which brings a lot of inconvenience to work. It is difficult to trace back the responsible party if the appliance is lost or broken.

There are mainly the following management issues:

(1) Inaccurate grasp of the main vehicle factory’s needs, resulting in more or less delivery of appliances, and increased workload;

(2) Failed to record the equipment transferred to the outsourcing factory, how many the outsourcing factory took, how many returned, and how many utensils were left unclear;

(3) The equipment is often damaged or lost, and it is difficult for the responsible party to trace it back, causing great losses to the main car factory and logistics company;

(4) The current inventory management operations are carried out manually, with a large number of personnel and a large workload, which cannot form a refined management;

(5) It is impossible to track the turnover of the equipment, and there is no accurate data statistics on the efficiency of the turnover use, which is not conducive to the reasonable deployment of equipment resources;

(6) There is no accurate data basis to evaluate the work performance of logistics companies.

3. Solutions:

Using advanced intelligent identification technology, through a complete information management platform, the whole process tracking management of the appliance is realized. Standardize the management process, and the information is transparent and accurate.

3 RFID application solutions

1. The overall business process

(1) Pasting of RFID tags

According to the management requirements of the main car factory, different pasting methods are used according to different appliance forms: pasting, lashing, bolts, etc. The label size and style can be customized according to actual needs. Each RFID tag is written with a unique identification number. You can know the appliance information through induction.

(2) Newly purchased equipment storage process

(3) Receiving and warehousing of appliances

(4) Maintenance work

(5) Inventory work

By using the handheld computer to take inventory, the warehouse manager only needs to scan the goods information in the warehouse to generate the inventory table. The accuracy rate is high, and the inventory time can be saved by more than 80%.

(6) Stocking operations

(7) Outbound operations

(8) Location map

Customize the location display map according to the actual warehouse area, and display the usage status of the warehouse through the location map. Click on a different area to view the inventory of the area; query a certain material, which can be displayed on the location.

Summarize:

For traditional manual management, the RFID manager has the following advantages:

(1) The current position of the appliance can be tracked in real time. The inventory information of the appliance is clear at a glance, and the management is clearer;

(2) Using advanced intelligent recognition technology to replace traditional manual operation, greatly improving work efficiency and increasing the turnover rate of appliances in the warehouse;

(3) Through software management, the data is more accurate, and the data statistics report related to the appliance can be quickly extracted, and can be printed and generated in Excel at will, which is convenient for checking with the main vehicle factory. Through some secondary development, it can also realize the data docking with the main car factory SAP;

(4) Realize the traceability of the entire process of appliance use. When damage or loss (exceeding the turnover period) occurs, the circulation record of the appliance can be quickly traced.

(5) Automatic warning function. When the time the appliance is out of the warehouse exceeds the turnover period, the system automatically warns for easy recovery. Reduce the loss of appliances;

(6) Operation instructions such as stock preparation and delivery are automatically transmitted through the system to improve the efficiency of operations in the warehouse.

[ad_2]