In-plant logistics vehicle management system for large-scale production enterprises

[ad_1]

Large-scale enterprise groups require a large amount of goods to be transported every day, so the in and out of vehicles are complex, frequent, and mobile, and there are certain difficulties in management. It is easy to produce management loopholes and cause unnecessary management problems; currently most of the groups Manual recording methods are still used for the management of incoming vehicles, which not only wastes time and paper, but also the accuracy and standardization of information cannot be guaranteed.

In response to the above problems, Chuangyi Technology uses wireless sensor networks and RFID radio frequency identification technology, through the installation of RFID hardware and corresponding functional software, and develops a complete and efficient set of in-plant vehicle intelligence based on the actual situation of vehicle management. Dynamic management system.

From the perspective of the actual vehicle management problems in the factory, the RFID vehicle dynamic management and positioning system in the factory was developed. This system focuses on solving the management problems of logistics vehicles, realizing the dynamic monitoring of the vehicle area, bringing convenience to management personnel, and improving logistics operations. Strict management of vehicle processes reduces manual recording time by personnel, improves accuracy, avoids paper waste, optimizes various processes, and brings greater benefits to the group.

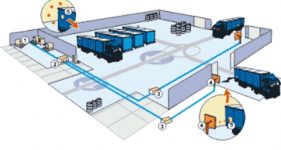

This system is designed in accordance with the actual situation of the group logistics and runs independently. The logistics vehicles are designed according to four functional areas, namely the arrival waiting area, weighing area, cargo loading and unloading area, and factory weighing area. The vehicle dynamic management system mainly installs card readers at the entrances of the above four areas to realize the management functions of vehicle tracking, positioning, data storage, loading and unloading operations visualization, loading and unloading operation time presets and alarms, and remote visualization viewing.

2. Function introduction

2.1 System function

2.1.1 Vehicle information writing;

2.1.2 Vehicle movement area monitoring;

2.1.3 Record of vehicle in and out time;

2.1.4 The preset time of vehicle operation time exceeds the alarm;

2.1.5 Visualization of vehicle information in the factory;

2.1.6 The traceability form is automatically generated;

2.1.7 Data storage;

2.2 Function realization

2.2.1 Vehicle information writing

While weighing the trucks, the staff in the factory issued on-board information tags to the incoming logistics vehicles, and entered the relevant information of the vehicle in the system computer: vehicle owner’s name, vehicle owner’s mobile phone number, license plate number, vehicle brand, vehicle model and this The loading items required for the second approach, the estimated time to use, and the relevant data generated by each item are bound to the tag. The tag ID number is unique and will not be confused with other tags;

2.2.2 Vehicle movement area monitoring

Install card readers at the entrance of each transportation and loading area of the factory. Whenever a logistics vehicle arrives in a new area, it will be read by the card reader installed at the import, and the vehicle location information at this time will be displayed in the relevant location;

2.2.3 Record of vehicle in and out time

When the staff is issuing the vehicle information label, the system records the time of issuance. When the vehicle completes the loading and unloading work in the factory area and weighs at the factory, the driver needs to return the vehicle information label, and the system automatically records the return time.

2.2.4 Vehicle operating time preset and time exceeding alarm

When the vehicle receives the in-vehicle information tag, the administrator presets the operating time for the vehicle to enter the site according to the content of the vehicle to be operated. When the vehicle has not proceeded to the next step beyond the operating time, the system will prompt the administrator for the time exceeded .

2.2.5 Visualization of vehicle information in the factory

The computer of the administrator can visualize the vehicle information in the factory, showing how many vehicles there are in the factory, what kind of vehicles they are, and the estimated time of completion of the vehicles, so as to facilitate the administrator to carry out vehicle scheduling. If a large-screen display is installed in the waiting area of the entrance, such information can be put on the large-screen display, and the driver in the waiting area can also see the relevant information.

2.2.6 Automatic generation of retrospective orders

When the administrator distributes the vehicle information label to the driver, fill in the vehicle owner’s name, vehicle owner’s mobile phone number, license plate number, and the goods to be loaded and unloaded this time, and the system automatically generates a ticket number, which is the date plus the serial number. , Will never be repeated, but if there is a dispute, you can find the retrospective list in the system.

2.2.7 Data storage:

All data generated in the Internet of Things system will be automatically saved in the system. The administrator can set the length of time the data is saved. The system will automatically delete the expired content at a preset time point, and configure storage hard drives of different sizes according to the specific needs of the administrator , It is convenient for the administrator to view the backup when an accident or dispute occurs.

[ad_2]