Tuotu Technology’s overall solution for e-commerce logistics management

[ad_1]

The logistics industry, including e-commerce formats, has the following characteristics:

1. SKU categories are complex

Small chain supermarkets have about 1,000 SKU categories, large and medium-sized supermarkets have more than 10,000 SKU categories, and large e-commerce companies usually have SKU categories close to 100,000. Such a complex SKU category has different storage and transportation requirements, and the logistics management work is very complicated;

2. Frequent changes in SKUs on sale

Facing the ever-changing demands of the retail market, manufacturing companies must constantly adjust their product structure and constantly introduce new ones to adapt to changes in market demand and gain market competitive advantages. This will lead to continuous adjustments and adjustments to new product logistics management in the circulation and logistics links. Update, with incomplete statistics, the update rate of the products on sale in small supermarket chains is about 20% each year;

3. Diversification of SKU packaging

For the same commodity, as the market demand changes, the packaging will be different. The logistics management link of the circulation enterprise needs to be able to adapt to this change, and carry out conversion and quantity comparison of packaging at all levels;

4. Large single in, small single out

Generally speaking, circulation companies rely on their terminal store resource advantages to obtain purchase price advantages from upstream companies with large orders, and conduct retail sales at terminal market prices to obtain spread profits. In this format, the warehousing and logistics links of circulation companies must be able to simultaneously provide large-volume centralized batch warehousing and small orders scattered out of the warehouse processing capabilities, which is particularly prominent in e-commerce companies;

5. SKU inventory security management

In the ever-changing market environment, the safety of inventory is very important to circulation companies, which is mainly reflected in: on the one hand, the quality of the inventory goods will directly affect consumers’ purchase intentions and shopping experience; on the other hand, the actual inventory The number of holdings will affect the company’s inventory holding cost and the saleable guarantee of the sales terminal;

6. Efficient execution of warehouse operations

In the warehousing link, large quantities of delivered goods need to be quickly accepted and put on shelves to form a saleable inventory; in the outbound link, a large number of scattered orders need to be efficiently sorted, sorted, shipped out and distributed, so that it can be satisfied. Sales demand of retail terminals;

7. Reasonable planning for SKU storage

SKUs on sale in circulation companies usually need to be classified according to their sales volume by ABC. In the warehousing link, it is also necessary to plan the storage location reasonably according to the ABC classification of SKUs, so as to help warehouse operators improve the efficiency of logistics operations. For example: A-type SKU is stored at the bottom of the shelf and close to the entrance and exit; C-type SKU is stored on the top of the shelf and is inconvenient in and out of the warehouse, picking positions, etc.;

8. Inventory batch management

The logistics industry in the circulation industry has strict management of SKU inventory batches. On the one hand, the warehouse needs to be able to distinguish the batches of incoming SKUs to meet the needs of first-in-first-out (FIFO) and first due, first-out. On the other hand, for quality Defective SKUs need to be able to trace and locate faulty products through batches.

9. SN management requirements

Out of the need for traceability and safety management of sold products, e-commerce companies usually manage the SKUs of some categories with SN (single product code) management to ensure the effectiveness of offline product returns and traceability.

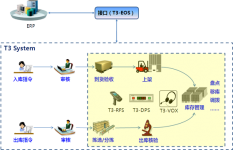

Based on the above-mentioned characteristics of logistics management in the circulation industry, Topo Technology has launched an overall solution for the logistics management of the T3 circulation industry on the basis of the T3 system. Circulation enterprises and e-commerce enterprises deploy and implement the overall T3 logistics management solution for the circulation industry, which can realize the whole process, refinement, and refinement of the logistics management of circulation enterprises.IntelligentThe management model meets the needs of circulation enterprises in warehousing, transportation/distribution, logistics billing, settlement, etc., while improving the corresponding speed of logistics and the real-time and accuracy of inventory.

Solution composition

The overall solution for logistics management in the T3 circulation industry integrates T3-WMS (warehouse management system), T3-RFS (wireless handheld operating system), T3-DPS (electronic tag assisted picking system), and T3-TMS (transportation/distribution management system) , T3-EOS (data interface platform) and T3-VOX (voice picking system) and other subsystems. Each subsystem can operate independently to meet the management needs and business needs of specific links of the logistics organization of circulation enterprises or third-party logistics enterprises, and can also be integrated and integrated to achieve all-round coverage of enterprise logistics management.

Solution benefits

By implementing the overall solution of T3 circulation industry logistics management, enterprises can obtain the following management benefits:

1. Improve work efficiency

By applying T3-WMS inventory, picking, and shelf optimization strategies in the solution, supplemented by technical means such as RFS, DPS, and voice picking, it can effectively improve the efficiency of enterprise warehousing operations by more than 35%;

2. Improve job accuracy

The system’s electronic operation method can greatly improve the accuracy of picking, outgoing, inventory and other operations, thereby increasing the accuracy of inventory, up to 99.9%;

3. Reduce operating costs

The solution can not only reduce the cost of cargo damage and cargo difference caused by operation errors from the perspective of improving the quality of operations, but also greatly reduce the quantity and quality requirements for human resources, so as to achieve sustainable cost reduction. At the same time, through the implementation of the system Application, can realize paperless office, reduce the consumption of paper products for operation, and reduce the overall operation cost to 55% of the original level;

4. Real-time control of inventory data

Through the implementation of the solution, decision makers and managers can grasp the inventory status of each warehouse, each region and even the global SKU in real time, laying a data foundation for accurately formulating purchase plans and allocation plans;

5. Improve operation assessment

With the support of the solution system, it is possible to conduct quantitative assessments on various links of warehouse logistics operations and related operators, and improve the operation assessment methods;

6. Assistant decision support

Through the analysis of logistics operation data, it is possible to grasp the information of operation efficiency, operation volume, operation cost consumption and personnel working status at a macro level, and provide auxiliary support means for leadership decision-making;

7. Improve resource utilization

The application of the solution can standardize the sorting, placement and flow of goods in the warehouse, which can effectively increase the utilization rate of the warehouse and reduce the demand for warehouse space. At the same time, it can also improve the use efficiency of operators and corresponding equipment through system optimization. From a point of view, the effective utilization rate of the warehouse can be increased to 90%;

8. Improve customer service

Through the implementation of the solution, companies can reduce the error rate of warehousing operations to less than three ten thousandths, avoiding the decline in customer service level and customer satisfaction caused by operational errors;

9. Full traceability of services and goods

The traceability of the solution to services and goods can reach the logistics operation level, and the traceability accuracy can reach the smallest batch of raw materials and finished products, which can form a complete and fine-grained traceability information chain, which can meet the needs of enterprises for product and Comprehensive requirements for service traceability management, traceability efficiency can reach 99%;

10. Reduce the work intensity of employees

The solution not only provides optimal suggestions for operators in terms of job allocation strategy, but also avoids the time and energy consumption caused by operators’ unfamiliarity with the physical location and goods, and reduces the workload by 70% compared with manual accounting and operation methods.

[ad_2]