RFID smart logistics system solution

[ad_1]

introduction

The RFID-based container management system fixes electronic tags on the container,ReaderInstalled at the entrances and exits of operating vehicles or ports, through non-contact information reading and writing, the data information connection between the container and the management system is realized. The 900M band radio frequency identification system can read and write multiple stationary or moving tags at the same time. The latest magnetic metal tag developed by JieXun Electronics has the following characteristics: strong adsorption; easy to install and recycle; reusable; large amount of stored information; long service life; good confidentiality. The antenna and reading and writing equipment are installed on the container running channel and the container lifting equipment. The reader can read and write the information in the container transportation to the electronic tag, and connect to the container management system for data exchange to realize the automatic identification and real-time of the container. manage.

The objectives of project implementation include:

(1). Container-related information (such as box number, company code used, box type, box type, gross weight, net weight, etc.) is stored in the electronic tag, and the information can be read and transmitted in a wireless, fast, and automatic manner to avoid Errors that may be caused by manual input.

(2). The container is transported by the consignment vehicle to the storage yard from entering the port inspection channel until it is loaded on the ship. The entire process of foreign containers from unloading to storage yard and out of customs is tracked and monitored, and information such as containers, consignment vehicles, occurrence time, and operators are recorded.

(3) The automatic management of the storage yard carries out information exchange through the wireless network, and the reader installed on the stacker can automatically identify the container number, and quickly and accurately inquire about the location and status of the container stack.

(4) Carry out the registration management of the vehicles undertaking the consignment, install the vehicle electronic tags, realize the automatic collection of vehicle information during the consignment process, cancel the complicated document procedures, shorten the time for entering and exiting the gate, and reduce the workload of the personnel.

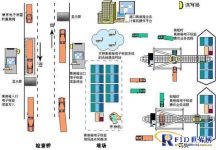

1. The project implementation plan is shown in the figure below:

Central monitoring center system: monitor the operation of other systems, carry out information interaction with other systems, carry out container information management and consignment vehicle information management, data statistics and analysis, carry out freight settlement, and provide customers with container information inquiry services.

Work site monitoring system: monitor and record container information, consignment vehicle information, occurrence time, operators, etc., and statistically analyze the conditions of various containers.

Yard container management system: monitors and records the information of containers passing through the gate of the port inspection channel, the corresponding haulage vehicle information, and the operators. Container stacking location information management in the yard, through the reader on the stacking vehicle and the display screen placed in the cab to quickly and accurately find the location of the container, and complete the function of placing and finding containers according to the container yard map.

Ship loading and unloading monitoring system: monitors and records relevant information during loading and unloading of ships, and effectively records the information of containers during loading and unloading operations.

1. System key technology

The RFID-based container management system uses a 900MHz frequency band system. Including the installation of 1-2 electronic tags in the designated position of each container, installation of an electronic tag on each registered consignment vehicle (electronic tags are generally installed on the front windshield of the consignment vehicle), and inspection of the passage at the port Install readers at the entrances and exits of the storage yard, install readers on the stackers and forklifts in the storage yard, and display the reading information on the display screens of the stackers and forklifts. Readers are installed on loading and unloading equipment such as quayside portal cranes, site gantry cranes, container forklifts, and container reach stackers. During the operation of lifting and transporting containers, the electronic tags of the containers are identified to improve the accuracy and efficiency of operations.

2. System workflow

The working process is as follows: install electronic tags with relevant information on the designated locations of vehicles and containers, and when the vehicles pass through the dedicated verification channel of the freight yard, the system automatically collects relevant information, and displays the information that guides the vehicle to the place on the outdoor display screen for inspection The staff confirms that the information is correct and releases it. At the same time, the information collected by the system is passed to the dispatching center, and the dispatching center directs the loading and unloading equipment to perform related operations. Realize the whole process control of container operation in the port.based onRFID The technical container management system strengthens container monitoring capabilities, provides customers with relevant information, realizes automated yard management, and reduces the workload and human errors of container management personnel.

2. Main functions:

It can meet the requirements of loading and unloading equipment such as quayside bridge cranes, quayside portal cranes, site gantry cranes, container forklifts, container reach stackers, etc., in the process of lifting and transporting containers, read and write container electronic tags;

Meet the requirements of automatic reading and writing of container electronic tags when container trucks pass through the junction of the container port area;

With read-write function and storage history record function.

Enhanced information security and confidentiality performance;

Can realize information exchange with existing local area network;

The system is compatible with handheld reading and writing equipment;

The recognition distance can be adjusted according to the environment (1-10 meters).

Compatible with multiple identification protocols to meet the reading requirements of different tags;

The reader supports RS485, RS232, and Ethernet interfaces;

The reader supports the power control function.

Application environment of container electronic tags: not affected by harsh environments such as rain, snow, fog, extreme heat, severe cold, noise, machinery, vibration and impact.

Reading data and management system can realize seamless connection;

Electromagnetic compatibility: in line with national standards GB9254 and GB/T17618;

The electromagnetic radiation safety of the human body meets the standard requirements of the “Electromagnetic Radiation Exposure Limits and Measurement Methods” of the China Radio Commission;

Established real-time management of container information based on the electronic tag identification system;

Established a container data exchange platform (to achieve electronic data exchange between ports and shipping);

Information exchange standardization: The industry EDI/XML standard has been introduced to support the international trade logistics industry information exchange standard.

3. System network transmission

Three, system equipment introduction

The automatic identification technology adopted by the container electronic tags, electronic license plates and automatic identification equipment in the system are long-distance RFID products. The electronic label of the container is installed in the designated position of the container, and the electronic license plate is installed in the front windshield of the consignment vehicle. The read-write distance of the reader is greater than 5 meters, and it has a multi-tag reading function.

[ad_2]