Next day Zigbee logistics warehouse pallet management system

[ad_1]

Foreword: Traditional warehouse management relies on a non-automated, text file-based system to record and track incoming and outgoing goods, relying on human memory and habits to find goods in the warehouse, and the internal management of the warehouse is completely implemented manually. Therefore, the efficiency of warehouse management is extremely low, and the scale of the warehouse that can be managed is also very small. With the rapid development of China’s economy, the scale of logistics warehouses is getting larger and larger, and the traditional warehouse management model does not adapt to the development of the market.

At present, the warehouse management of most enterprises has begun to use computer data system management, and still use paper records and manual input to the computer for collection and statistics. It is impossible to realize the automation of the system; it is also impossible to realize the positioning of the items in the warehouse. The future development direction of smart warehouses must be: automatic warehousing, automatic inventory, automatic identification and positioning…

1. System introduction

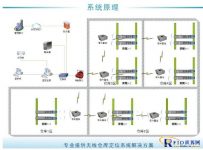

The next day, the Zigbee logistics warehouse pallet management system was designed and developed using radio frequency technology. It is used to manage the entire process of goods from storage to storage, mainly including the functions of goods storage, search and positioning of goods, maintenance records of goods, inventory of goods, and goods out of storage. At the same time, the system provides functions such as area management, item type management, customer management, base station layout, shelf layout, equipment low-power management, equipment fault management, etc., so that the system can achieve the purpose of warehouse automation and intelligent management. The card reader base station in the system receives the radio frequency signal from the positioning card, and wirelessly transmits it to the next card reader base station or transmission interface. The transmission interface processes the information and uploads it to the monitoring host, combining with map monitoring to realize functions such as query and positioning.

At present, radio frequency technology is bringing a huge change to the supply chain field. It can identify the incomparable advantages of barcodes such as long distance, fast, hard to damage, large capacity, etc., simplify the complicated work process, and effectively improve the efficiency and transparency of the supply chain. . Based on Zigbee technology, Shenzhen Yiri Technology Co., Ltd. conducts automatic data collection on the data of various operations such as warehouse arrival inspection, warehousing, delivery, allocation, shifting, inventory counting, and item positioning to ensure warehouse management. The speed and accuracy of link data input ensure that the company can timely and accurately grasp the real data of the inventory, and reasonably maintain and control the company’s inventory. Through scientific coding, it is also convenient to manage the batch and shelf life of items. Using the system’s positioning management function, you can also grasp the current location of all inventory materials in time, which is conducive to improving the efficiency of warehouse management.

2. Function introduction

2.1 Inbound management

Bind a locating card to the item. When entering the warehouse, you can enter the item number, locating card number, item type, item description and other related information. After the information is reported to the host through the base station, it will be displayed in the item information column of item management.

2.2 Item query

Provides a variety of query methods, which can be used to query items according to their area, shelf number, item type, item number, location card number, maintenance status, and storage time.

2.3 Item positioning

Item positioning provides three positioning methods: item number positioning, item card number positioning and item type positioning. Enter the item number or card number or select the item type and click the card number bound to the item to be located to generate sound and light alarms. At the same time, the location information displayed on the warehouse map can be based on the location on the map and the sound and light alarm information of the positioning card. It is very convenient to find the located items.

2.4 Item maintenance records

There are two indicator lights on the positioning card, which can record the current status of the item according to the status of the indicator. There are four states: the red light flashes once, the buzzer sounds once, and the red light and street light flash twice. The device beeps twice, the green light flashes three times, the buzzer sounds three times, and the red light flashes four times. The buzzer sounds four times. The four states can respectively represent the four different states of the item: missing parts, pending maintenance, under maintenance, and maintained.

2.5 Item inventory

Item inventory can automatically count various types of items and quantities without manual operation.

2.6 Item outbound statistics

Outbound statistics include item number, item type, in-stock time, out-of-warehouse time, destination and other information. It can be inquired according to item number, item type, whereabouts and time.

2.7 Automatic record of item position movement

When an item moves from one place to another, the system will automatically change the area according to the location information from the positioning card, without manual processing.

Three, system characteristics

3.1 Wireless and automated management

The system adopts wireless radio frequency technology. All base station and positioning card information uploads are automatically uploaded wirelessly. Information statistics can be completed without manual collection, realizing automatic and intelligent management.

3.2 Acousto-optic positioning

Ordinary barcode technology and RFID technology cannot achieve the positioning function. When you need to find an item, you must first find the area where the item is located, and then go to the area to find one by one, without any prompts on the item itself. The system needs to locate an item directly when searching for it, and the area where the item is located can be displayed on the map. At the same time, the location card bound to the item generates an audible and visual alarm, which has indicated its specific location, making it extremely convenient to find the item.

3.3 Multiple states are available

The positioning card can define a variety of different states according to the sound and light. Each state can represent a different meaning of the item, such as missing parts, waiting to be maintained, under maintenance, and already maintained. It can also mean other meanings.

3.4 Automatically track the location of items

When an item is moved, the track of the item is tracked in real time, and the current position of the item is automatically updated.

Fourth, the software interface

The location information of the card reader base station and shelf can be displayed on the warehouse map in real time, and the area division can also be displayed by corresponding processing:

●GIS map display

●Equipment layout diagram display: card reader base station information, shelf information, relative position, etc.

●Positioning display: flashing will appear on the shelves of the map during positioning, indicating that the positioned items are on the shelves in this area.

Five, technical parameters

◆Location card

The positioning card is bound to the object, and the card continuously and automatically sends signals to the card reader base station to report its real-time location information.

Location card features:

Low power consumption, the battery can be used for more than 6 months.

The communication distance with the card reader base station is long, up to 200 meters in a straight line.

With sound and light alarm function.

With low-power alarm function.

There are four states: the red light flashes once, the buzzer sounds once, the red light and the street light flash twice, the buzzer sounds twice, the green light flashes three times, the buzzer sounds three times, and the red light flashes four times. The four beeps can represent four different states of the object.

Waterproof and dustproof design; no radiation damage.

Working voltage DC 3.0V

Emission current ≤180mA

Activation current≤40mA

Standby current≤1uA

Transmission, activation, standby time ratio (1.2±0.2) ms: (5±1) ms: (5000±100) ms

Alarm working current≤170mA

Alarm working time 20 minutes

Wireless frequency band 2.4GHz

Communication protocol ZigBee (IEEE802.15.4)

Dimensions 70mm×60mm×20mm

Shell material flame-retardant ABS plastic grease

Binding method The tie is bound to the item

Weight 80g

Battery type alkaline dry battery

Battery specification 1.5V/700mAh

Battery life can be used for more than 6 months

◆Card reader base station

The wireless transmission distance with the transmission interface is long, up to 200m.

The wireless path can be automatically selected, and another path can be automatically selected when a path is interrupted, and the information transmission is reliable

Working voltage DC 3.0V

Maximum working current 0.2A

Wireless jump transmission with transmission interface transmission type

The maximum transmission distance to the base station is 200m

Maximum wireless output power -20dBm ~ +18dBm

Battery working time is not less than 3 months

Waterproof grade IP54

Dimensions 280*280*130 mm

Weight 2.85kg

Shell material flame-retardant ABS plastic grease

The future is an era of the Internet of Things, and we can go as far as we can think!

[ad_2]