RFID logistics warehouse management system solution

[ad_1]

Introduction to Logistics Warehousing Management System

In order to solve the common problems of the above-mentioned enterprise warehousing and logistics departments, Shulun Technology Co., Ltd. uses advanced RFID technology, combined with automatic control technology, wireless communication technology, computer network technology, and makes full use of the characteristics of electronic tags that can be read in a large amount in an instant. The characteristics of long-distance recognition and the characteristics of large data storage capacity have designed this modern warehouse management system.

The system automatically collects the data of each operation link in the warehouse management, such as arrival inspection, warehousing, outbound, allocation, shifting, inventory counting, etc., to ensure the speed and accuracy of data input in each link of warehouse management. Ensure that the company grasps the real data of the inventory in a timely and accurate manner, and reasonably maintains and controls the inventory.

Through scientific coding, it is convenient to manage the batch and shelf life of items. Use the system’s location management function to grasp the current location of all inventory materials in time to improve the efficiency of warehouse management.

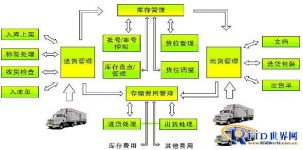

System composition (picture)

Logistics warehousing management system functions

1. Automatically identify and record the goods in and out of the warehouse, and realize the automation of information collection;

2. Inventory counting uses handheld computers to update the data of the inventory management system in real time to realize intelligent inventory management;

3. Automatic allocation of cargo space, automatic picking of goods, real-time check of the status of cargo and cargo space, realizing refined and visualized warehouse management;

4. Install electronic tags on the forklift to locate the current position of the forklift in real time to achieve transparency in asset management;

5. The on-board computer automatically guides, optimizes the movement trajectory of the forklift, reduces energy consumption, and realizes the standardization of business processing;

6. Add the error reminder function to the misplaced goods according to the ID number of the cargo location label to realize one-to-one pallet and cargo location;

7. According to the ID number of the pallet label, it can automatically determine whether the goods are legal to enter and exit, and improve the management security;

8. It is simple and convenient to install electronic labels on the pallet, and it can be reused to realize the uniqueness of the identification.

System flow chart)

Logistics warehouse management system benefits

1. This system uses IoT RFID high-tech to realize data collection automation and improve the real-time data collection in the logistics process;

2. Fully integrate enterprise logistics information resources, track site and inventory conditions in real time, and improve inventory availability;

3. Good data management, reduce the number of data input errors and error corrections, reduce the damage rate and the write-off of expired products;

4. Efficient operation efficiency, increase warehouse throughput, and reduce warehouse labor costs;

5. Improve service level, improve employee and customer satisfaction;

6. Enhance the market competitiveness of enterprises and better attract high-end customers.

7. Save energy, protect the environment, maintain sustainable social and economic development and harmonize with the environment.

15850124084 Ma Bin www.digican-rfid.com

[ad_2]