Medical Supply Chain Management System Based on RFID Technology

[ad_1]

1. Background

According to a report from the World Health Organization, the proportion of counterfeit drugs in the world has exceeded 10%. According to data from the Chinese Medical Association, at least 200,000 people die from counterfeit drugs and improper use of drugs each year. The international community has attached great importance to the tracking of medical products. The US FDA has passed legislation to strengthen the application of drug transportation, sales, access, and traceability systems.

At present, the supply chain management of medical products in the medical field mainly uses barcode recognition technology. Although barcode technology is quite mature and has been widely used worldwide, it also has some insurmountable defects:

The same barcode code can only be defined as one type of product in management, and cannot identify a single product in the same product;

The barcode is relatively visualized, and only one barcode can be recognized at a time, and the work efficiency is very low when batch processing is required;

The barcode must be attached to the paper, so it is easy to be damaged or contaminated, which makes it difficult or unrecognizable;

Due to the limited storage information of the barcode, once the barcode is printed, if it needs to be changed, the original barcode cannot be used again;

The barcode cannot penetrate transparent or non-metallic materials such as wood, paper and plastic, and it must be recognized when there are no obstacles at a close distance;

Bar codes are easy to forge and cannot be used as a basis for anti-counterfeiting traceability.

With the continuous development of information technology, the efficiency and level of supply chain management has become a decisive factor for business success. The information system based on barcode technology has been unable to keep up with the pace of informatization. The information collection methods are backward, and the data collection is not timely. As a result, the real-time synchronization and accuracy of information cannot be guaranteed in all links of the supply chain. The supply chain urgently needs a new generation of information technology systems.

2. RFID application

RFID radio frequency identification technology is a popular automatic identification technology in recent years, it can quickly and accurately complete the original data collection required for computer information processing. It has large storage capacity, long-distance penetrating batch reading, and its unique ID number in the world. These characteristics make the application of RFID technology in the medical supply chain management will completely change the traditional supply chain model. , To maximize resource sharing and improve the operating efficiency of the entire supply chain.

The application of RFID technology in medical supply chain management can realize all-round real-time monitoring of medical products from production, warehousing, sales to consumption, avoid public medical safety issues, and play an important role in rectifying and regulating the medical product market. At the same time, at each node, RFID can not only make the collection of medical product information more efficient, but also real-time sharing of information on the supply chain, it can also make the entire supply chain transparent, reduce inventory, and reduce costs.

Using the new generation of RFID information technology as the carrier, build a pharmaceutical supply chain management traceability platform to realize the tracking and monitoring of the whole process of drugs from raw materials, processing, production, storage to sales, standardize the pharmaceutical production and sales market, and reduce unnecessary intermediate circulation links. Control product inventory, improve production efficiency, establish an enterprise’s brand image, increase its market share, and provide a real-time, transparent and accurate information management platform for enterprises, consumers and government regulatory agencies.

3. System design

As the general agent of ThingMagic in China under JADAK, Shenzhen Quanshunhong Technology Co., Ltd. provides all major operators and integrators with the full range of ThingMagic products. At the same time, the company has always provided professional technical teams and high-quality services. Preferential prices, to provide our customers with world-class RFID equipment solutions and high-quality after-sales service.

3.1 System framework

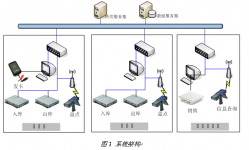

The circulation path of pharmaceutical products in the supply chain mainly includes procurement, manufacturing, logistics transportation, distribution, warehousing, distribution, retail, and customers. The pharmaceutical supply chain traceability platform based on RFID technology is composed of RFID tags, RFID readers, information collection systems at each logistics node, RFID middleware, and supervision information platforms. RFID tags and hardware facilities are the content of the perception layer of the entire solution. The use of radio frequency technology’s multi-target recognition, moving target recognition, long recognition distance, long service life, non-destructive, uniqueness, etc., realizes rapid and automatic data collection at the operation level , Focusing on manufacturing, distribution and retail, laying the foundation for the tracking and tracing of pharmaceutical products.

The system architecture diagram is as follows:

RFID medical supply chain management uses special card issuers or RFID printers to initialize electronic label information and establish electronic archives of medical products. At each circulation node, a four-channel fixed reader will complete the storage and exit of medical products. The equipment mainly completes the sales business, and the handheld device can conveniently and flexibly carry out inventory and information inquiry.

3.2 Process analysis

The overall business of the pharmaceutical supply chain management system based on RFID technology mainly includes: manufacturing links, distribution links, retail and end-user links.

3.2.1 Manufacturing process

The application of RFID technology in the manufacturing process can realize the recording, tracking and identification of products in the entire pharmaceutical supply chain, reducing the error rate of manual operations, reducing labor costs, and improving work efficiency and production benefits.

In this link, manufacturers use disposable RFID electronic tags, which are pasted on the outer packaging of drugs during the production and packaging process. The electronic tags are used as the carrier of information transmission. The electronic tags contain the type of drug, batch number, expiration date, wholesaler, etc. in the EPC data area. Information, and upload the information to the system server to establish a database of basic drug information to facilitate information statistics and related staff inquiries.

When medicines are in and out of the warehouse, use a fixed reader to read the electronic label information on the outer packaging of the medicine, and upload the information to the system data server according to the read information and the quantity information in and out of the warehouse. The management center system server performs processing according to the type information. Classification and statistics, real-time display of inventory information, inventory location information, outbound information, etc., to improve the work in warehouse management. Using a handheld reader, you can take inventory of drugs in the warehouse.

3.2.2 Distribution link

When pharmaceutical products flow from the manufacturing company to the distributors, they will pass through the distribution company’s receiving channel and the RFID reader device in the receiving channel to automatically read the RFID tags of the single pieces, boxes, and pallets of the pharmaceutical products entering the distribution company. And check with the pre-arrival notice received in advance, realize the inspection without opening the box, and the difference alarm, and improve the efficiency and accuracy of the receipt.

When the medical product is out of the warehouse, select the corresponding drug out of the warehouse according to the order information, and upload the out-of-warehouse drug information and the out-of-warehouse quantity information to the management center system database server, update the inventory information and form an out-of-warehouse document; the out-of-warehouse document (issue The manifest) arrives at the lower-level retail organization along with the medicine, and confirms the operation.

3.2.3 Retail Link

According to the delivery note provided by the distributor, the information in the electronic label of the drug outer packaging is read through the handheld reader and checked with the delivery note information provided by the wholesaler. If the information is consistent, the information will be uploaded to the management through the network The central server, if the information is inconsistent, contact the dealer for processing, and upload the verification information and processing methods to the management center server through the network.

When selling medicines, provide corresponding medicines according to the needs of users, and upload the medicine information, quantity information, and user information to the management center server to form an out-of-warehouse electronic document.

3.2.4 End users

After the end user gets the medicine, according to the sales list provided by the seller, the information in the electronic label of the medicine outer packaging is read through the handheld reader, and checked with the sales list information provided by the seller, and can be accessed through the Internet. The management center server queries and confirms drug information.

3.3 Implementation benefits

RFID technology does not need to rely on visible light, nor does it need to be able to identify RFID tags in a specific direction and range. This technical feature of RFID reduces the cost of traditional manual scanning and improves the efficiency of large-scale supply chain automation applications, thereby reducing the high error rate and inefficiency caused by the artificial environment.

RFID tags have attracted much attention in various industries due to their long recognition distance and large storage capacity. After the use of RFID tags on pharmaceutical products, all companies in the supply chain can quickly realize information sharing and information interconnection, and help all companies in the supply chain to greatly improve the efficiency of management of goods in and out of the warehouse, so as to obtain product feedback more quickly and accurately Information optimizes the entire hospital supply chain. The application of RFID technology will bring expected benefits to the entire pharmaceutical supply chain:

The efficiency of warehousing and inspection is greatly improved. When the medical product affixed with the radio frequency tag arrives, the warehousing channel equipped with the RFID reader will automatically identify the radio frequency tag. According to the obtained label information, the warehousing operation of the product will be completed. The traditional reliance on manual labor to complete the goods warehousing and receiving process greatly simplifies, saves a lot of manpower operations, and improves public efficiency.

Improve inventory accuracy. After the use of RFID tags on medical products, the inventory of medical products can be quickly counted, which not only improves efficiency, but also makes data management accurate and timely, and at the same time improves the accuracy of medical product inventory.

The delivery speed is greatly improved. After the application of RFID technology, the outbound management of medical products will be intelligent and automated. When medical products with RFID tags pass through the warehouse exit channel with RFID readers installed, the RFID readers will automatically identify the information on the medical product tags and automatically complete the delivery operation without manual scanning operations. Greatly mentioned the outbound efficiency.

The information data lag is effectively improved. After the use of RFID technology, the flow of goods and data are closely linked, which effectively eliminates the situation that the goods have been reached before and the information system has not processed them. This is conducive to the real-time understanding of the current status of the goods in the upstream and downstream enterprises of the supply chain. It saves labor costs and mentions the operating efficiency of the supply chain.

Avoid fake and shoddy products. Because RFID tags are encrypted and not easy to be copied, the use of RFID tags on each medical product can play a role in product anti-counterfeiting.

[ad_2]