Suggested Plan for Implementing Light Weapons Supervision

[ad_1]

Chapter 1 Overview

This system is designed for the automation and digitization of military light weapons supervision, and is mainly used for military firearms and other light weapons supervision. The system uses RFID technology to penetrate the key links of the general warehouse, student team depots, and transportation processes of light weapons such as firearms to realize automatic identification of military firearms and automatic information collection, and provide the collected and processed data to the supervisory software system through middleware. An effective and accurate digital platform for intelligent management of the entry and exit of firearms and other light weapons, warehouse supervision, use and maintenance.

In response to specific needs, based on previous implementation experience, this implementation proposal will adopt RFID technology to achieve the use and safety management of firearms, so as to achieve effective supervision.

Chapter 2 System Selection and Working Principle

1. RFID technology principle

RFID (Radio Frequency ID) is a “radio frequency identification” technology, which is a non-contact automatic identification technology. The basic principle is to use radio frequency signals and their spatial coupling and transmission characteristics to realize automatic identification of stationary or moving objects to be identified, and to obtain related data for identification, statistics, and processing by the back-end system. The frequencies currently used by RFID span low frequency (LF), high frequency (HF), ultra high frequency (UHF),

Multiple frequency bands such as microwave.

2. Features of RFID technology

RFID is an easy-to-control, simple, practical, and flexible application technology. Its unique advantages are beyond the reach of other identification technologies such as barcodes, magnetic cards, and IC cards. It can support both read-only work mode and read-write work mode without contact or aiming; reading can be completed in the moving process; supporting simultaneous reading and distributed data collection; storing information can be changed freely; free to work in each Under a harsh environment; a high degree of data integration can be carried out. In addition, because the technology is difficult to be counterfeited, RFID has a very high security protection capability. This technology can complete information input and processing without manual contact, optical visualization, and manual intervention, and the operation is fast and convenient.

3. RFID applicable fields

The RFID application field has already involved all aspects of people’s daily life, and will become a basic technology for the construction of the information society in the future. Typical applications of RFID include: warehouse management, logistics distribution, production line automation, product sales in the supply chain; combat support systems and inventory automation systems in the military and government industries; container and package management in the transportation field, highways Toll and parking fees; in the manufacturing industry for the visual management of production and inventory (such as tobacco, pharmaceuticals, automobiles, etc.); in the field of food safety for the traceability management of agricultural, forestry, fishery, animal husbandry and non-staple food; in the medical industry for the production and distribution of drugs , Patient care, medical waste tracking; RFID can also be used in various application fields such as book and file management, personnel and vehicle access management, positioning and object tracking, environmental perception, ticket anti-counterfeiting, and pet and wild animal tracking.

4. RFID application system composition

The radio frequency identification application system generally consists of four parts, namely, electronic tags, reading and writing equipment, middleware, and business application management software. In the application, the electronic tag is attached to the item to be identified. When the item to be identified with the electronic tag passes through the reading range, the reader will automatically take out the agreed identification information in the electronic tag in a contactless manner at a long distance, thereby realizing automatic The function of identifying items or automatically collecting item identification information.

Chapter III Implementation Plan Design

1. Implementation requirements

In view of the current management process analysis, the needs of this project are mainly reflected in the two aspects of use management and safety management, which are specifically reflected in:

General firearms warehouse: control of gun expenditures in the warehouse, supervision of guns in the warehouse

Cadet team divided warehouse: gun expenditure warehouse control, gun supervision in the warehouse

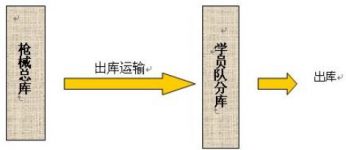

(Figure 1 Schematic diagram of process analysis)

2. Application process and implementation plan design

2.1 Application process

The general warehouse and the student team can be divided into warehouses to use the system network to connect various monitoring subsystems, and to conduct unified management in the monitoring data center.

A. First install the RFID gun passive tag on the butt. The appearance of the tag can be designed according to the butt.

(Figure 2 Schematic diagram of gun RFID tag installation)

B. The guns arrive at the general warehouse and are put into storage, and the RFID gun reader/writer is used to automatically collect data and count the incoming guns. The incoming guns are placed in 2 rows and placed in the gun cabinet. The number of guns in the warehouse can be counted through a handheld reader. Go to the outgoing guns from the trainee team’s sub-library, place the outgoing guns into the trolley in 2 rows, and automatically collect data through the RFID gun reader to count the outgoing guns. The outgoing guns are put into the gun box, and the RFID safety lock can be installed outside the gun box to ensure transportation safety.

(Figure 3 Schematic diagram of the installation of the gun cabinet in the main warehouse)

C. Arrive at the sub-base of the student team and use RFID technology to automatically manage the access of guns.

2.2 General warehouse management

A set of gun tag reading and writing equipment is installed at the door of the warehouse, and the gun tag reading and writing equipment is connected to the general warehouse control computer through the network. The specific indication is as follows:

(Figure 5 Schematic diagram of general warehouse equipment deployment)

2.2.1 Store in and out

When loading carts with tagged guns in and out of the warehouse, the fixed read-write equipment installed at the entrance and exit of the warehouse collects the information on the tags of the carts and uploads it to the general warehouse supervision system. The system can automatically obtain the number of guns in and out of the warehouse.

Use handheld computers to count the guns in the warehouse

The number of outgoing guns can be set through the console to automatically determine whether the outgoing guns are legal.

According to the location of the gun cabinet in the warehouse, the handheld device can also be used to collect information on the gun tags on the in and out cart, and upload it to the management terminal of the console. The general warehouse supervision system can automatically obtain the number of guns in and out of the warehouse.

2.2.2 Packing guns

2.3 The trainee team is supervised by the warehouse

The security lock tag reading and writing equipment is installed at the entrance and exit of the sub-store, and one set is initially designed and installed. The fixed reading and writing equipment is connected to the warehouse console computer through RS485 or RS232. The specific instructions are as follows:

(Figure 5 Schematic diagram of the equipment deployment of the trainee team warehouse)

3 System architecture design

3.1 Overall structure

According to the implementation requirements and application process analysis, the entire RFID management system of this project is composed of three levels, and its structure is shown in the following figure:

(Figure 6 Hierarchical diagram of firearms and light weapons supervision system)

As can be seen from the figure, the system is composed of an application software layer, a middleware layer and a hardware layer.

Hardware layer

The hardware layer is responsible for the coding of electronic tags; collects the identified device information, uploads it to the RFID middleware, and accepts the configuration information of the upper layer. Including passive RFID tags used to identify firearms, passive RFID firearm tag readers and handheld readers.

Middleware layer

The middleware layer is responsible for processing equipment management, data filtering and integration of the hardware layer, passing the processing results to the application software layer, and extracting configuration information to set, operate, and take effect on the hardware layer. Including hardware servers, software middleware servers.

Application software layer

It is an application software system that completes the supervision of firearms and other light weapons.

3.2 Hardware system composition

The system hardware is mainly composed of fixed reading and writing equipment, handheld reading and writing equipment, and active electronic tags. in:

Firearm passive tag reading and writing equipment and antenna:

Installed at the entrance of the main warehouse and the student team’s sub-warehouse, the equipment mainly collects information on gun expenditures and the guns in the warehouse. The reading and writing distance of the device is adjustable at 1-2 meters.

Handheld reading and writing equipment:

Read the information of the gun tags in the library and take inventory in real time.

3.3 Software system composition

3.3.1 Middleware system

RFID middleware is a kind of message-oriented middleware (Message-Oriented Middleware, MOM). Information (Information) is transmitted from one program to another or more programs in the form of messages. Information can be sent in an asynchronous manner, so the sender does not have to wait for a response. The function of message-oriented middleware is not only to pass information, but also to interpret data, security, data broadcasting, error recovery, locate network resources, find a cost-compliant path, prioritize messages and requirements, and Services such as extended debugging tools.

The middleware system can define interfaces according to the configuration of the application software.

(Figure 8 Middleware system structure)

3.3.2 Application software system for firearms and light weapons supervision

The application software system has three layers, the application layer, the middleware and component layer, and the database layer.

The component and middleware layer accepts requests from the application layer and completes operations such as storage, query, and modification of the database layer. At the same time, the various levels of the software system are implemented in accordance with their respective standards, and full consideration has been given to safety to ensure the safe and stable operation of the system under complex conditions.

(Figure 9 Firearms and light weapons monitoring application software system)

[ad_2]