The overall solution of RFID in bathroom injection molding manufacturing

[ad_1]

The whole system of this scheme has the characteristics of fast identification, intelligent control, high reliability, high confidentiality, easy operation and easy expansion. Establish a safe and reliable product production process, and the system can track the corresponding product information from the information stored in the RFID electronic tag of the device. It is convenient and real-time to query the relevant record information of the production process to provide a basis for quality traceability.

1. Project background

The bathroom manufacturing industry often encounters the following problems in the manufacturing process:

Data collection adopts traditional manual entry method, which has large errors and inaccurate data;

The production data cannot be updated in real time, and the production line information is asymmetric, which restricts the increase in production capacity;

The order production process cannot be tracked and checked in real time, and the delivery date is delayed; the bar code label is easy to be damaged, and the bar code gun cannot be identified in batches and quickly collect data information;

The efficiency of employees is not uniform, the division of labor is uneven, and the work efficiency is low;

Barcode data collection requires a lot of manual work, and labor costs are high.

2. System advantages

It has the characteristics of fast identification, intelligent control, high reliability, high confidentiality, easy operation and easy expansion. Establish a safe and reliable product production process, and the system can track the corresponding product information from the information stored in the RFID electronic tag of the device. It is convenient and real-time to query the relevant record information of the production process to provide a basis for quality traceability.

Third, the application of intelligent bathroom manufacturing scenarios

1. Product injection

The system allocates the corresponding mold injection products according to the production order; the handheld RFID read-write device scans the RFID electronic tags on the mold on-site; records the use time and counts the product qualification rate in injection molding; the recorded information is updated to the background server through the RFID handheld device.

2. Plating of ceramic products

Automatic identification, recording and monitoring of product materials, production processes, semi-finished products, and finished products; visual management, real-time discovery and processing of production problems, traceability of product authenticity, whereabouts, storage, process records, producers, quality inspectors, and production dates, etc. Information, analyze the causes of bad products.

3. Hardware products electroplating

After the product is hung, the surface process such as electroplating, PVD coating, spraying, etc. is carried out; the gantry is placed at the node of each process and the RFID reading and writing equipment is fixed; the hanger passes through the gantry, and the RFID reading and writing device automatically recognizes the label information on the hanger ; The background updates the time point of the corresponding hangers and counts the number of hangers.

4. Product testing and transfer

The quality inspection and packaging of the down-linked products are transferred to the transit logistics box, and the qualified rate of process processing is counted; the down-linked products are loaded into the transit logistics box by classification, and the RFID reading and writing equipment scans the logistics box transfer time, product model, quantity and other information and updates to Back-end server; logistics boxes are stacked in pallets or storage locations allocated by the system.

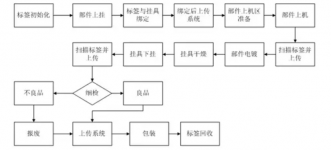

5. Application process of electroplating workshop

The electronic tags on the logistics frame are read through the RFID read-write device, combined with the back-end software management system, to realize the automated and intelligent management of the warehousing.

1. Commodity storage

When the goods enter the warehouse, the RFID reader at the entry port automatically scans the RFID tags, collects the information of the items stored in the logistics box, compares the warehousing list, and checks the quantity and model of the goods; manual intervention for error correction, there is a pallet, and the pallet information is checked with the goods information Binding; according to the instructions of the system, the goods will be transported to the designated location and placed in classification.

2. Commodity stacking

The logistics boxes are stacked according to certain rules; one pallet is stacked with a certain number of goods; each pallet has an RFID tag. Before the goods are put on the shelf, all the logistics boxes on the pallet are bound to the pallet RFID tag, and the pallet corresponds to the goods on it.

3. Commodity inventory

The RFID handheld device first scans the location label and then scans the goods to be counted; the handheld device compares the collected product information with the background server; the server compares the difference information in real time and displays it on the handheld device; the difference is checked on site, and the inventory information is handheld The machine is updated to the background server.

4. Commodity delivery

According to the outbound product order, the system allocates the pallets stacked in the designated location; the forklift drags the goods out through the exit equipped with RFID reading and writing equipment; the reader scans the RFID tag to collect the information of the items stored in each logistics box; compare the outbound Single information, check the quantity and model; if there are errors or omissions, perform manual error correction.

[ad_2]