An RFID-based logistics distribution center information system plan

[ad_1]

Overview

The distribution center is a modern circulation facility that is engaged in the distribution of goods and the organization of the delivery to users, and realizes sales or supply at a high level. With the continuous growth of business volume and the continuous improvement of customer demand, distribution center management is also facing increasing challenges, especially how to reduce the cost of logistics center. Improve the operating efficiency of the logistics center. For this reason, the distribution center not only needs to be equipped with automated logistics equipment and technology, but also has a modern logistics management information system and modern management methods. The development of Internet of Things technology, especially the application of RFlD, will greatly improve the operational efficiency of distribution centers.

This paper proposes a logistics distribution center information system solution based on RFID technology in accordance with the demand for logistics business informatization in the distribution center.

1. Introduction to RFID

The full name of RFID (Radio Frequency Identification) is the radio frequency identification technology 111121. Its basic principle is to use radio frequency signals and their spatial coupling and transmission characteristics to realize automatic machine identification of stationary or moving items to be identified. It is a non-contact Compared with the current popular bar code, the automatic identification technology of the new type generally takes ten seconds to read a bar code manually. The machine read time is two seconds. With RFID tags, only O.D. is required for reading. It takes 1 second (or even shorter), and does not require manual intervention, which greatly improves efficiency.

RFID tags have the following characteristics:

High anti-counterfeiting, each label can have the world’s unique code, large enough information storage space to read and write data, can be encrypted by special means, and cannot be copied.

Long service life, no mechanical wear, no mechanical failure, passive work, can work in harsh environments, anti-fouling, and long data reading distance.

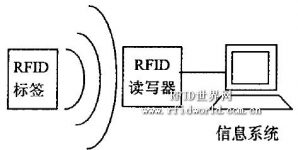

RFID tags can be well combined with computer information systems to form solutions for various applications. When an article with an RFID electronic tag passes through the reader, the electronic tag is activated by the reader. The information carried in the tag is transmitted to the reader and computer system through radio waves to complete the automatic collection of information. The computer application system performs corresponding information control and processing work as required. The whole process is shown in Figure 1. No manual intervention is required, and the degree of automation is high. Based on a simple RFID system, combined with existing network technology, database technology, middleware technology, etc., a distribution center IoT information processing system consisting of networked readers and a large number of mobile or static tags can be constructed.

Figure 1 Schematic diagram of RFID system

Currently, the price of RFID tags is about one yuan each. In addition to supporting costs, the total cost of the entire application system is still relatively high. But RFID technology basically complies with Moore’s Law. With the increase in output and the continuous expansion of application scale, the total cost of the system will be greatly reduced.

2.Distribution Center Information System Solution

The basic operation process of the distribution center is shown in Figure 2: After the supplier sends the goods to the distribution center, after checking the purchase plan and performing the product inspection, the goods are sent to different locations on the shelf for storage, and the goods are regularly or irregularly performed inventory. After an order is placed, find out the storage location of the required goods, pick it up, ship it, and then deliver it to the corresponding customer. If the goods are missing, they need to be restocked. Each step of the operation in the figure must be accurate, timely, and have traceability, controllability and coordination.

Figure 2 Flow chart of distribution center operations

Correspondingly, the distribution center information system is divided into the following main processing modules: purchase module, storage module, inventory module, replenishment module, and distribution module. Let’s introduce them one by one below.

1) Purchase module

When the goods are delivered by the supplier, they are equipped with the R WD label, which records the name, characteristics, delivery place, arrival place, delivery note number, order details, etc. of the goods in the electronic label. When the goods arrive at the distribution center, the RFID tags are read in batches by the reader and passed to the information system of the distribution center. The purchase plan has been entered in the information system in advance. In this way, it can be compared with the order details and other information read from the RFID to complete the comparison and acceptance of the goods. After the acceptance is completed, on the unloading platform, the information system determines the storage location of this kind of goods according to the pre-determined warehousing principle and the quantity of goods in stock. And write the RFID tag of the goods in the storage location of the logistics center through the reader.

2) Storage module

The goods are placed on pallets when they are in the warehouse, and the forklift driver can read the storage location of the goods from the RFID tags of the goods through the handheld reader. If it is to close the warehouse, the goods will be sent to specific locations, and there will be a reader near these locations. By reading the RFID information and sending it to the information system, the information system will update the inventory quantity of this kind of goods in real time. Storage location. If it is to be put on the shelf, the goods will be sent to a specific shelf for storage. There will be a reader above the shelf. Similarly, after reading the R and D label information in the goods, the information system will update the information of the goods in real time. Inventory quantity, storage shelf.

3) Inventory module

Another advantage of RFID technology is that it greatly reduces manpower during inventory counting, and it can even complete inventory counting automatically. Through the RFID reader in the cargo storage warehouse, the inventory of the goods can basically be completed in real time. Each RFID reader will pass the read information to the information system, and the information system will perform a unified summary processing, so that accurate information about the inventory of various goods can be obtained. Managers can quickly identify and correct inefficient operations. So as to achieve rapid supply and minimize storage costs.

4) Replenishment module

By entering customer orders into the information system, plus a certain inventory control strategy. Can get the inventory required for various goods. And inventory counting can conveniently provide actual inventory data of various goods. After comparative analysis of the two. The information system can accurately determine which goods need to be replenished and which goods are overstocked.

5) Picking module

In traditional logistics operations, sorting and distribution take up 60% of the total labor force used, and errors are prone to occur. After the distribution center accepts the customer’s order and enters the order into the information system, the system can print out the picking list: including the location and quantity of the goods. The sorting personnel pick the goods in the warehouse according to the picking list printed out by the computer. In addition, the sorting personnel use hand-held RFID readers. Write order information, customer information, etc. into the RFID tag of the checked out goods. When the goods leave the warehouse, the RFID reader at the warehouse passageway (doorway) can quickly read this information, and the information system will obtain this information. Compare with the original order. I immediately know if there is any error in the inspection and shipment.

In a distribution center with a relatively high degree of automation. Various automatic sorting machines can also read the RFID tag information, branch the goods to different chutes, and reach the designated area through the conveyor belt. The efficiency of distribution can be greatly improved. Through the integrated application of RFID and information systems (computer technology, network technology, database technology), the transmission speed of logistics information and the accuracy of data can be greatly improved, and real-time tracking of logistics can be realized.

The goods inventory, incoming and outgoing information, order information of the entire distribution center can be reflected to the management staff in a timely manner through the computer. It helps managers to carry out effective inventory control and corresponding operational decisions, shorten the circulation cycle of goods, and reduce the operating costs of the distribution center. On the other hand, due to the use of RFID tags, the accuracy of data can effectively avoid the occurrence of product backlogs, shortages, and expiration of shelf life caused by problems such as wrong accounts and wrong goods. And these all help to reduce the operating costs of the distribution center. Thereby reducing the cost of goods circulation.

3.Concluding remarks

We know that the promotion of any new technology takes a while, and it took more than 20 years for barcodes to develop to such a degree. The information system solution of logistics distribution center based on RFID technology proposed in this paper can provide reference for the application of RFID in the development of logistics distribution center informatization.

[ad_2]