Application of active RFID technology in the real-time collection system of temperature and humidity in the cold chain

[ad_1]

An Introduction

With active RFIDWith the rapid development of technology and applications, the industry has gradually realized the important application of temperature sensing systems based on active RFID technology in cold chain logistics. The active RFID tag is integrated, and the temperature data is obtained in real time through the temperature sensor, and then transmitted to the connected RFID tag for storage. The data obtained by the RFID tag is read when it enters the reading range of the reader for use. Through this method, it is possible to realize early warning when the temperature changes during the transportation/distribution process, or to record the temperature changes in the process, so as to help identify the quality changes that may be caused by temperature changes and the specific time of occurrence, and help Recognition of responsibility for quality accidents.

The working method of the RFID system is very simple. As long as the temperature collected by the temperature sensor is regularly written into the chip of the RFID tag, when the RFID tag receives the RFID reader antenna signal, the temperature data in the RFID chip is uploaded to the RFID reader and processed by the back-end system. This system can monitor the temperature change of a managed object in real time, and realize real-time monitoring and early warning management. It is also possible to read all point-to-point supply chain temperature data at one time, generate a static temperature change chart, and simply complete the supervision of temperature changes in the supply chain. Through this method, it is possible to realize an early warning when the temperature changes during the delivery/distribution process, or to record the temperature changes during the process, so as to help identify the quality changes that may be caused by temperature changes and the specific time of occurrence, and help Responsibility determination for quality accidents.

System Features

1. Simple operation;

2. Low cost of use;

3. Built-in high-energy lithium battery power supply, long battery life;

4. Long-distance reading and writing, without manual intervention;

5. No need to leave the item;

6. RFID tag provides ID code, large amount of data storage;

7. It can record temperature data continuously, with accurate time record, easy to define responsibility, and convenient for information traceability;

8. Can be expanded to 256 KB storage capacity.

System advantages

1. It can quickly grasp the temperature condition during transportation, which is the most important in freshness management;

2. Promote the improvement of freshness management in the process of distribution (improve shipping methods, select logistics routes);

3. Comply with food safety supervision requirements, food safety quality control HACCP requirements;

4. The temperature index can be set dynamically, which is convenient to use.

RFID technology is one of the development trends of cold chain logistics information technology. Using RFID technology, temperature changes can be recorded on the RFID tag to manage the freshness and quality of products in real time. At present, a relatively complete RFID industrial chain has been formed in China, and it has become one of the largest high-frequency RFID tag producers in the world. In 2008, the entire industrial market reached 6.58 billion yuan. RFID application is undoubtedly a bright spot in the field of information system integration in the future. Among them, the “RFID cold chain temperature management system” is bound to provide consumers with reassuring food and make new contributions to human well-being.

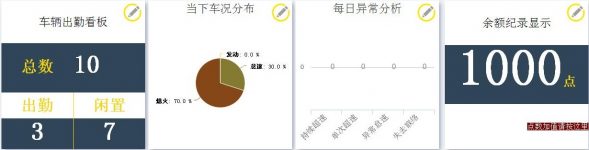

Platform page display

Platform Home

Platform settings

Cold chain temperature and humidity platform

Location map of cold chain vehicles

Cold chain system cheat sheet

[ad_2]