Chaolun RFID Warehouse Management System

[ad_1]

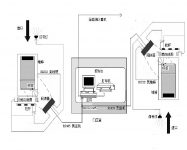

1. System overview

Chaolun RFID warehousing solution is Chaolunfei Intelligent Technology Co., Ltd.’s comprehensive solution for the application of RFID in the warehousing field. Based on the experience of informatization implementation, the system provides enterprises with RFID application mode analysis based on self-developed RFID reading and writing equipment, realizing the automation, informatization, and intelligence requirements of enterprise logistics operations, and at the same time realizing the integration of RFID technology and enterprise informatization system. Seam butt joints to ensure that RFID technology exerts the greatest benefit in enterprise logistics operations.

2. Basic principles

RFID is an advanced and powerful technology. It is based on unlimited radio frequency technology and can be used as a means of identifying materials. In addition to storing a unique identification number, RFID can also store a large amount of useful information related to materials and transmit it securely through wireless. The RFID tag will be encapsulated on the surface of the material, which contains various information will be stored in the chip in the center of the tag. The information contained in the label can be read and updated within the controllable range by the card reader working with it. The RFID card reader can have multiple interfaces and methods to connect with the back-end software system for more complex logic processing. RFID technology is different from the current common bar code technology. RFID tags can carry a larger amount of information, can communicate with longer examples, and are flexible in usage.

The RFID system has three components:

RFID tags

RFID tag, the chip in it will store the unique identification and other updated information; from the appearance point of view, the tag can also have a variety of different packaging forms. From the perspective of power supply, tags are divided into two types: active and passive.

RFID card reader

The RFID card reader shoulders the important responsibility of how to read any RFID tags within the monitoring range in real time, and is responsible for transmitting the read information to the back-end software system through the appropriate network.

RFID middleware

RFID middleware is the “heart” of the entire system. It obtains various real-time information about front-end tags and processes them in real time according to customer needs.

Because RFID tags are readable and writable, they are especially suitable for occasions where data content needs to be changed frequently. It plays a role in data collection and system command transmission. It is widely used in warehouse management, transportation management, production management, and materials in the supply chain. Tracking, identification of vehicles and shelves, anti-theft of commodities in stores, especially supermarkets, etc.

Three, system characteristics

(1) Advanced collection methods: Make full use of the data collection functions of barcode collection equipment or RFID equipment itself, and adopt GPRS/GPS network communication technology and wireless local area network technology to realize real-time data collection and mobile operations of various supporting equipment.

(2) The collected data is complete and accurate: The system is based on a handheld computer PDA device or an RFID mobile data collector (CL-A300 or CL-A930), which can store a large amount of bar code information into the device or directly transmit it to the server through the network, with high collection efficiency , The accuracy and rate are greatly improved.

(3) The information transmission channel is two-way and fast: the real-time data acquisition system realized by GPRS/GPS network communication technology and wireless local area network technology will maintain the two-way interaction between the handheld device and the server, and the data can be transmitted to the server in time through the handheld device. The server can send instructions to the device from time to time to achieve two-way fast communication.

(4) The system is safe and reliable: the establishment of the bar code asset system has set up a detailed security backup and recovery mechanism, realizing hot backup of data from time to time, and providing operation logs and personnel authorization. The on-site equipment uses high-performance hardware products and networks The product makes the operation of the collection system more stable and reliable.

(5) Friendly interface and convenient operation: the system not only realizes all the functions on the original display terminal (DT300 or DT930) and has been Chineseized, but also expands many new functions. The user interface of the Windows Mobile-based PDA system is friendly and beautiful. , Easy to operate.

(6) Advanced technology and good scalability: It adopts advanced computer application technology and has good scalability. The open system structure and long-term life cycle can meet the needs of sustainable development in the future. It can easily realize seamless data connection with enterprise ERP, CRM and other systems.

In warehouses, the most widely used radio frequency technology is access to goods and inventory counting, which can be used to automate operations such as inventory and retrieval. In the entire warehouse management, combining the receiving plan, picking plan, and shipping plan made by the supply chain planning system with radio frequency identification technology can efficiently complete various business operations, such as designating storage areas, picking up on shelves, and Replenishment etc. In this way, the accuracy and speed of operations are enhanced, service quality is improved, costs are reduced, labor and inventory space are saved, and at the same time, misplacement, misdelivery, theft, damage and inventory and shipment of goods due to the entire logistics are reduced. Loss caused by errors, etc.

RFID technology reduces manpower during inventory counting. The design of RFID is to automate the registration of goods. It does not require manual inspection or scanning bar codes during inventory, which is faster and more accurate, and reduces losses. RFID solutions can provide accurate information about inventory conditions, allowing managers to quickly identify and correct inefficient operations, thereby achieving rapid supply and minimizing storage costs.

[ad_2]