Jiangsu Dongda Integrated Logistics Innovation Solution

[ad_1]

In today’s global market, competition is fierce. More and more companies use “make-to-order production”, “zero inventory management”, “multiple batches and less batches” to coordinate all links of the supply chain by integrating the supply chain of products. Ensure efficient, timely and minimal cost delivery of products to end users. In this process, the difficulty of logistics management also increases, inventory information is inaccurate, shipment error rate remains high, transportation and distribution are unreasonable, and no-load Many problems, such as high rates, plague enterprises. Therefore, it has become an urgent task to establish a logistics information system that can interact with customers, provide real-time query, browse, online cargo tracking of service information, realize distribution route planning, logistics resource scheduling, cargo inspection and other services. With the help of the logistics information system, it can not only reduce the cost of some enterprises, improve the efficiency of communication between enterprises and customers, but also increase the reaction speed of both parties’ transactions, so that customers can truly experience the value-added experience brought by value-added services.

There are many links in the logistics application process. In this case study, the two major links, warehouse management and distribution management, which are frequently used by RFID handheld terminals, are explained. The application methods and business processes are described in detail below.

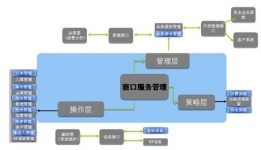

The overall framework of the system:

One warehouse management

Warehouse management is the core part of the enterprise information logistics system. In warehouse management, accurate and precise inventory of inbound and outbound data must be achieved. Jiangsu Dongji’s innovative logistics solutions can quickly and efficiently achieve precise and scientific management of warehouses. .

1.1 Block diagram of the deployment and implementation of the warehouse management system

The overall warehouse management system includes three major links: inbound management, inventory management, and outbound management. The overall structure is as follows:

1.2 Process of warehousing management system

Warehousing management specifically includes important links such as warehousing notification, quantity counting, confirmation of receipt, and handling of shelves. The handling of abnormal situations includes warehousing rejection, cross-docking and other links.

1.3 Outbound management system process

Picking out of the warehouse is a highly procedural operation, and it is one of the most important operational links in warehousing logistics operations. It has a very close relationship with other systems (distribution system, kanban distribution instruction system, etc.). Based on various outbound information (allocation, sorting, etc.), this system uses radio frequency technology to scan barcodes to confirm the accuracy of various outbound operations (manufacturer, product name, quantity, etc.). Important links in outbound management include acceptance Order, confirm picking wave, start picking, check out warehouse, etc.

1.4 Asset inventory

The system supports a variety of inventory methods: dynamic inventory, regular inventory and irregular sampling inventory, etc. According to the scope of inventory, the system can provide multiple functions such as full inventory, warehouse area inventory, cargo category inventory, and single product inventory. After entering the actual quantity, the system can automatically calculate the inventory difference. After the inventory difference is confirmed, it can be connected with the two functions of “Inventory Adjustment” and “Scrap” to complete the inventory result processing. If there is a inventory difference, the system supports re-inventory. . The designed system supports the working mode of using the RF data terminal for inventory.

The operation of the warehouse inventory system is shown in the figure below:

Two distribution management

The general distribution process includes three major steps: stock preparation, tally, and delivery. Here we focus on the application of handheld terminals in the delivery process.

Delivery operation is the end operation of the distribution center, and it is also an important link in the entire distribution process, including product loading and actual delivery. To complete these operations, you need to plan the division of the distribution area or the distribution line arrangement in advance, and the order of the distribution line selection To determine the order of product loading, and carry out product tracking, control and handling of unexpected situations during the delivery of the product.

The following is the overall distribution map.

2.1 Tracking on the way

The handheld terminal is combined with the GPS system, and the intelligent dispatching system can automatically update the transportation status with the information returned by the GPS, so as to realize the tracking and monitoring of the whole transportation task. The logistics monitoring subsystem is a combined application of GPS/GIS and electronic seals, which can monitor the real-time route, driving conditions, parking and opening times and places of the delivery vehicles.

The role, input and output of three handheld terminals

3.1 What problems are solved

1. Process informatization, real-time tracking of goods, improvement of data lag, and improvement of customer satisfaction, forming a fast and efficient logistics link;

2. Automatic collection, strong data reliability, reducing the error rate and also reducing the consumption of expensive paper operations;

3. Realize scientific storage and retrieval, precise inventory management, and improve the competitiveness of the enterprise;

4. Whether it is mail management or transportation operations, it saves a lot of operating time and improves work efficiency.;

5. Simple cargo plan, route arrangement and dispatch to avoid costly misloading;

6. Accurately monitor the conditions of drivers and vehicles and transmit dynamic routing decisions, which will help reduce transportation costs and some illegal behaviors.

3.2 Investment and return

At present, most express delivery companies use batch scanning guns and some low-cost non-durable PDAs. If the system is to be improved to information, the system will undoubtedly increase the initial cost input. This cost input may include: industrial-grade PDA+ System software development + SIM/UIM card purchase + WIFI environment construction + manpower training and other related expenditures. However, if a TCO (total cost of ownership) of enterprise operations is taken into account, the necessary equipment investment in the early stage will be in the future. To make up for it in a few years, let us first look at a TCO composition chart:

In the above figure, we can see that end-user operation and maintenance accounted for 55% of the total cost of ownership, while the initial capital investment accounted for only 12%. Combined with the survey of VDC Research Group, it is not difficult for us to draw a conclusion: low usage The high maintenance price of the consumer-grade PDA in the later period + the increasing support demand + the reduction in work efficiency caused by the series of reasons will be greater than any savings in the purchase price of the equipment. Therefore, the purchase of durable equipment is particularly important for the logistics and express industry. Important, so what return can the introduction of industrial-grade high-performance PDA bring, please see the table below for details:

[ad_2]