RFID paper industry application

[ad_1]

Application background

At present, more than 90% of paper-making enterprises have adopted ERP bar code management system, and the management informationization tends to take the lead compared with other industries. However, with regard to the new requirements raised by the warehousing and logistics management of finished paper at home and abroad, bar code technology has been unable to meet the mass production of large-scale production enterprises. Finished product warehousing and logistics management; faster, more accurate, automated information collection, and batch production have become a new manifestation of the current competitive strength of paper-making enterprises.

The main function

The bottom-up system consists of IoT perception layer, RFID middleware,RFIDWarehousing management system and enterprise ERP are composed of four parts. The main functions include: storage management, storage management, inventory management, transfer management, return management and other function expansion.

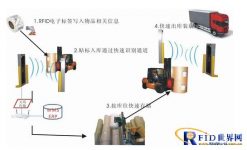

Each finished paper roll is affixed with an electronic label with relevant product information written before it is put into the warehouse. The forklift passes through the RFID automatic identification channel. The product and vehicle information is automatically read in batches. The information is uploaded to the management center in real time. The forklift enters the warehouse to store the goods and read the goods. Take the location label, and upload the information in real time via WIFI.

The forklift truck-mounted system enters the designated warehouse area according to the outbound information, and the outbound warehouse is automatically identified through the RFID channel, and the information is quickly read in batches and uploaded to the management center in real time.

Inventory inventory is batched, using 915M electronic label technology, which can read dozens of item information in batches at a time.

System Features

The use of RFID warehouse management greatly improves the efficiency of warehousing and inventory counting, reduces the rate of human error, and the accuracy rate reaches 99.99%

Warehouse management has a higher level of automation, which reduces the operation process and greatly reduces the operation time

Reduce labor costs

Greatly shorten the delivery time with customers,

Real-time traceability of product supply chain links

Warehouse operation management is more standardized

Regulate the sales market to prevent counterfeiting

[ad_2]