RFID solution for logistics turnover box management

[ad_1]

In recent years, as the number of retail enterprises in my country and the scale of logistics distribution have been increasing year by year, the use of logistics turnover boxes has increased. Following this, the management cost of turnover boxes has become higher and higher, and the phenomenon of large amounts of turnover boxes being lost is widespread. . In response to this problem, is there a feasible way to reduce the cost of turnover box management, avoid the loss of a large number of turnover boxes, and improve the efficiency of logistics operations? The answer is yes f. When the amount of turnover boxes in the enterprise is large, such as large quantities of turnover boxes in and out of the warehouse, if the inventory and records are completely carried out manually, the workload will be very large, and the enterprise will have to invest higher labor costs. , At the same time, errors are difficult to avoid. However, if RFID technology is introduced to manage the in and out of the turnover box in an automatic reading mode, it will not only be fast, but can greatly improve efficiency, and it can also save labor costs.

Unlike traditional bar code tags, RFID radio frequency tags can be read and written repeatedly, and the stored information can be compensated and modified.

For example, it is used for multi-functional containers containing items. In the future, it may be possible to use radio frequency identification technology to understand the individual containers in the entire pallet and the goods in the containers.

At present, RFID technology is bringing a huge change to the supply chain field, to identify the advantages of long distance, fast, not easy to damage, large capacity, etc., simplify the complicated work process, and effectively improve the efficiency and transparency of the supply chain.

application solution

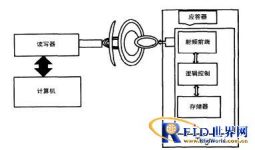

The basic RFID system consists of three parts: RFID tag (Tag), reader (Re ader) and application support software (Figure 1). The RFID tag is composed of a chip and an antenna (A ntenna), and each tag has a unique electronic code. The tag is attached to the object to identify the target object.

Figure 1 Basic structure of RFID system

1. The choice of RFID tags

RFID tags are divided into two types: Active and Passive according to different ways of sending radio frequency signals. Active tags actively send radio frequency signals to the reader, usually powered by a built-in battery, also known as active tags, which have a longer communication distance, but their price is relatively high, and they are mainly used in applications such as remote detection of valuables . Passive tags do not have batteries, and are also called passive tags. The energy required for the transmission of electric waves and the operation of the internal processor comes from the electromagnetic waves generated by the reader. After the passive tag receives the electromagnetic wave signal from the reader, it converts part of the electromagnetic energy into energy for its own work. Generally, the price of passive tags is relatively low, but their working distance and storage capacity are limited by energy sources. In logistics turnover box management applications, the working distance is usually within 2 meters, and the storage capacity requirements are not too large, so passive RFID tags can be used.

2. Selection of frequency band

The choice of operating frequency is a key issue in the application of RFID technology. It not only affects the performance and size of the tag, but also affects the price of the tag and reader.

There are multiple frequency bands in the working frequency of RFID, and different frequency bands have their own advantages and disadvantages. At present, the working frequency of RFID applied to the logistics turnover box mainly has two frequency bands: high frequency 13.56MHz and UHF UHF. The reading distance of high frequency RFID is relatively short, generally no more than 1.5 meters, but it can read through objects. The ability of tags is relatively strong: while the reading distance of UHF RFID is relatively long, generally about 3-9 meters, but the penetration reading ability is relatively poor. For logistics turnover box management, since the middle distance of the warehouse door is about 2 meters, and there is no need to penetrate the turnover box and various commodities, UHF portal antennas with a reading distance of about 3 to 9 meters can be used.

3. RFID tag installation

The RFID label processed by the self-adhesive packaging method can be attached to the place where the surface of the turnover box is not easy to be hit, so that the RFID reader can quickly and accurately identify it. Considering that during the use of the turnover box, it may hit the RFID label attached to the surface, which will cause the label to be damaged. At the same time, it is beneficial to the protection of the label against dust and water. The label can be embedded in the turnover box or sealed by plastic. The rear label is installed on the turnover box.

4. Information recognition

In actual logistics operations, it is usually necessary to quickly and accurately read a large number of turnover boxes with RFID tags in a short time. Therefore, an array antenna group (ultra high frequency) can be used to ensure fast and accurate Of reading.

The biggest advantage of using RFID technology to identify the turnover box is that it can read the turnover box information of a cage at a time. Compared with scanning the bar code one by one, it greatly saves time and labor costs.

Feasibility cost analysis

RFID tag cost analysis is the key to the success of commercial applications of this technology. Take the ordinary F90 inlay label as an example, if the quantity exceeds 100,000, a single label can be reduced to less than 1 yuan. With the advancement of integrated circuit technology and the expansion of application scale, the cost of RFID tags will continue to decrease. In addition, the increased costs of purchasing RFID readers and software systems are also key factors affecting RFID applications.

From the perspective of benefits, the application of RFID technology to logistics turnover box management can greatly improve operational efficiency, realize digital warehouse management (warehouse location management, fast real-time inventory), etc., make management more scientific, timely, and effective, and ensure the supply chain The high-quality data exchange will bring about a substantial increase in logistics efficiency, thereby reducing the overall cost of the system. In this way, the investment in the use of RFID is also worthwhile.

[ad_2]