RFID technology-based item tracking management system solution

[ad_1]

Program overview

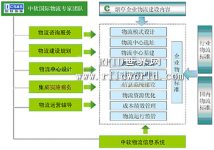

From the perspective of optimizing the supply chain, the Chinasoft logistics solution aims to build a digital, automated, intelligent, informatized and standardized logistics management system, integrate logistics resources, and realize information sharing. The system is composed of multiple core products. It is based on item tracking management and logistics resource management, focusing on storage, transportation, sorting, and distribution business, covering job scheduling, cost performance, and operation supervision.

Program details

1. Item tracking management based on RFID technology

Realize the tracking of the process of cigarette production offline, industrial storage, industrial storage, commercial storage and commercial storage. Track, monitor and trace all links of the supply chain, make information transparent, process controllable, and realize the integration of logistics and information flow.

2. Digital warehouse management

The warehouse management subsystem (WMS) relies on advanced supply chain logistics management concepts and integrates digital warehousing equipment to achieve refined and standardized management of all links from cigarette storage, storage, allocation, delivery, inventory, shift, picking, and delivery . Improve the efficiency of logistics operations and reduce operating costs, highlighting the advanced management concepts of modern logistics, and combining the characteristics of tobacco industry logistics. Its composition is shown in the following figure:

﹣ Warehouse Management System: The core of the digital warehouse management system, which plays the role of job scheduling, execution, and monitoring.

-Warehousing control system: used to control RFID, electronic display tags, RF, large screens, sorting systems and other auxiliary operation equipment, send/receive operation instructions, feedback operation results, and display operation information.

﹣ Software interface platform: used to exchange data with the industry’s cigarette production and operation decision-making management system, marketing system, supply chain system, ERP system, etc.

-Hardware interface platform: used to connect and maintain communication with RFID, electronic display tags, RF, sorting systems, large screens, etc.

3. Distribution route optimization and GIS decision analysis

Comprehensive utilization of 3G and route optimization technology is an effective means to reduce delivery costs, ensure delivery safety, standardize delivery services, and achieve flexible delivery. On the whole, the core functions of the application are mainly composed of three parts: GPS monitoring center system, automatic delivery routing system and GIS decision analysis system. On this basis, several extended functions such as GPS navigation, assisted delivery, delivery scheduling, delivery performance evaluation and decision support are derived. The application logic of the entire system is shown in the figure below:

﹣ GPS monitoring center system: Obtain electronic map data, GPS data, retail household data, and delivery vehicle/person data from electronic maps, GPS systems, CRM systems, and distribution systems, and further process them to visually display the real-time vehicle positioning data in On the electronic map, realize the operation management of the vehicle.

﹣ Automatic distribution delivery route system: Obtain map data, GPS data, retail data, delivery vehicle/personnel data, and order data from electronic maps, GPS systems, CRM systems, distribution systems, and telephone ordering systems, and perform calculations based on optimized algorithms , To form information that can be used to know the optimized driving route and stowage plan for completing the distribution operation, and hand it over to the distribution system for execution.

﹣ GIS decision analysis system: Obtain map data, GPS data, retail household data, delivery vehicle/personnel data, and orders from electronic maps, GPS systems, CRM systems, distribution systems, telephone order systems, marketing management systems, and monopoly management systems. Data, sales data, and monopoly data are analyzed on this basis to provide technical support methods and data foundations for leadership decision-making.

4. Logistics cost and job performance management

For many years, logistics has been widely recognized and valued by enterprises as the “third source of profit”, and the analysis based on logistics operation cost and the corresponding operation performance appraisal have become a weapon for enterprises to reduce costs and improve performance.

Logistics cost management can perform cost accounting according to accounting objects (departments, teams, customers, goods), including functions such as collection and allocation, quota management, budget management, and cost analysis.

Logistics performance management includes two parts: performance management of logistics personnel and performance management of logistics operations, including performance index setting, performance calculation, performance appraisal, performance analysis and other functions. The purpose of performance appraisal is to make the available resources (personnel, equipment, facilities, time, capital, materials, etc.) play the highest efficiency, and to provide a basis for investment decisions. The setting of performance benchmarks can refer to the average performance level of the industry, the highest comparable performance level, or the target performance level of the company.

5. Logistics network video monitoring system

The establishment of a network video monitoring system can implement remote digital management, strengthen security, improve on-site management efficiency, reduce management costs, and promote employee enthusiasm. The staff of the upper-level department in charge can understand the working conditions of the subordinate departments and staff in real time without going to the site in person, so as to facilitate their management, improve work management efficiency, and reduce costs caused by travel inspections.

The network video surveillance system can convert the traditional video analog signal into a digital signal and transmit it through the Internet, and can store the compressed video information in the server. Implement monitoring of key logistics links such as the warehouse area and the entrance and exit of the warehouse, and activate the alarm function. The administrator can turn on the motion detection or sensor through the system. Once a situation occurs in the motion detection area or the sensor detects a situation, the system can automatically turn on the alarm function through the setting of the program, and automatically turn on the video recording. Real-time occurrences are recorded in the system, eliminating the need to install expensive monitoring systems for key units, which can save a lot of expenses.

The networked video surveillance system is mainly composed of four major parts: network cameras (including integrated network cameras and network cameras composed of analog cameras + video encoders), IP network platforms, intelligent monitoring management software, and other value-added equipment such as servers, storage and displays .

value of customer

﹣ Enable customers to grasp the location, flow and quantity of products in a timely manner, and provide support for decision-making.

﹣ Provides an effective information management platform for the traceability of goods flow.

﹣ Provides a good information platform for the intermodal transportation of product production and sales.

﹣ Provides an efficient information collection channel for enterprise logistics information management, fully embodying the core of modern logistics management-realizing the agility of goods flow and reducing storage and management costs.

﹣ Improve the scientific management level of products and greatly improve the efficiency and benefit of warehouse management. Support industrial and commercial integrated warehouse management management, support property ownership management mode, support access batch management, support RFID-based electronic tray management, support electronic tray and cigarette code-based item tracking and traceability management, and support product flow-based management Dynamic warehouse management, according to the rules of first-in-first-out, work path & work time priority, weight balance and other rules to implement cargo position management, reduce warehouse honeycomb phenomenon, effectively improve the utilization of storage space utilization, and support one company with one warehouse, and one company with multiple warehouses , Multiple companies and one warehouse, etc.

﹣ Upgrade and improve the management model of traditional warehouses. Support the optimal scheduling and performance appraisal of job resources, and meet the performance cost management requirements of the job-based costing method.

[ad_2]