sh-rw warehouse item positioning and searching system based on semi-active RFID technology

[ad_1]

1 Introduction

1.1 Document description

The purpose of this program is to let integrators, engineers and users understand the design concepts, principles, overall planning and how to play a huge role in the warehousing field of IoT RFID positioning technology, and elaborate on the working principles and installation locations of related IoT devices. Information, so that integrators, engineering companies, and users can correctly understand the revolutionary changes brought by the Internet of Things in the warehousing field and the current deficiencies of the technology, and establish a correct understanding of the Internet of Things in the warehousing field. If you encounter any confusion or confusion during the reading process, please contact the program writer. Shanghai Renwei Electronic Technology Co., Ltd. has the final right to interpret this document.

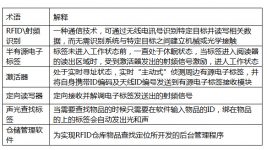

1.2 Explanation of terms and abbreviations Explanation of terms

2. Project background

2.1 Analysis of the status quo

Market competition is becoming increasingly fierce, and improving production efficiency and reducing operating costs are of vital importance to enterprises. At present, warehouse management systems usually use barcode labels or manual warehouse management documents to support their own warehouse management. However, the characteristics of barcodes such as easy copying, non-fouling, non-moisture-proof, and cumbersome operation, and the cumbersomeness of manual writing of documents, are likely to cause human losses, which make the current domestic warehouse management always have defects. For this reason, RFID (electronic label, radio frequency) Identification) technology came into being.RFID(Electronic tags, radio frequency identification) The application of this latest technology product can fundamentally solve the above-mentioned problems.

2.2 Significance of system construction

Realize cross-regional centralized management, distributed operation and real-time monitoring functions;

Efficiently complete various business operations, find items, improve warehouse management, and increase efficiency and value;

Improve the recognition rate of items in and out of the warehouse, and identify multiple items at the same time, to ensure that the number of physical items is consistent with the number of documents, and to improve the efficiency of entering and exiting pants;

Reduce the inventory cycle, improve the real-time performance of data, and dynamically grasp the inventory situation in real time to realize the visual management of inventory items;

Accurately grasp the inventory situation, optimize the reasonable inventory; grasp the status and changes of the warehouse environment in real time.

Observe the working conditions of the staff in the warehouse in real time and grasp the work progress;

Safely manage the warehouse to prevent illegal acts such as theft and vandalism.

3. System design

3.1 Principles of System Construction

The system development and construction follow the following principles:

Focus on overall planning

Based on semi-activeRFIDThe technical storage system consists of three parts. First, look at the core hardware of the storage system based on semi-active RFID technology (including: dual-frequency electronic tags, sound and light search tags, industrial-grade readers, directional readers, and 125K low-frequency activators. , Industrial-grade handheld readers); second, storage system software based on semi-active RFID technology (including front-end display software and background management software); third, middleware (including industrial-grade switches, cabinets, PCs, Servers, uninterruptible power supplies, etc.).

Based on independent research and development

The core technology of the system construction adopts the standard 2.4G and 125K low frequency trigger technology commonly used in the market. All the core equipment provided by the company has completely independent intellectual property rights, 2.4G micro power consumption technology, electronic tag sound and light search design, 125K cable antenna technology , Synchronous sending and receiving mechanism, etc. are all created by the company, so that the label has a very high service life and positioning accuracy, which is far beyond the domestic industry level.

Focus on future development

In the overall system architecture, service equipment selection, label function selection, basic data collection, etc., fully consider the realization of subsequent functions, taking into account the compatibility of the equipment, the scalability of the system, the scalability of functions and the diversity of applications;

Strengthen system specifications

System development and resource construction conform to a unified technical specification and characterization system, pay attention to the continuity and sharing of development work, and pay attention to leaving standardized data and control interfaces for subsequent system development and promotion. Unified development of technical indicators such as application technology, data storage format, signal transmission system, and interconnection interface mode;

Utilize construction benefits

The development and construction of the system should be combined with the actual situation in the supervision area, and the management of the warehouse should be further added on the basis of the existing system; in accordance with the construction ideas of overall planning, construction while using, and gradual improvement, the construction benefits should be fully brought into play.

3.2 The working principle of the system

First, according to the specific conditions of the warehouse area, a certain number of card reader base stations are placed to make the signal in the warehouse area fully covered.

Bind a RW-T738 acousto-optic search electronic tag to the warehousing item. When the warehousing is completed, the item and the location card are placed within the signal coverage of the base station. The card reader base station receives the location card information and uploads it to Transmission interface, the transmission interface is uploaded to the host, and the host obtains the specific location information of the item through software processing. When positioning, the area location of the item can be displayed on the host map. Combined with the sound and light prompt of the positioning card, the item can be found accurately and conveniently.

After the item is bound to the location card and stored in the warehouse, the information is uploaded to the system through the card reader base station, and the item information is displayed in the item information column in the item management, which can be based on the area of the item, item number, location card number, status, storage time, etc. Make an inquiry.

The indicator light of the positioning card and the sound of the buzzer have four states, which can indicate the four different states of the item. They are: missing parts-the red light flashes four times and the buzzer beeps four times, to be maintained- The red light of the location card flashes once, and the buzzer sounds once. During maintenance-the red and green lights of the location card flash twice, the buzzer sounds twice, and it is maintained-the green light flashes three times and the buzzer sounds three times. Press the button on the positioning card for a short time for about 1 second to view the current status of the item, press the button on the positioning card for a long time for more than 3 seconds to switch between the four states. The system will record the status change every time the status is changed, thereby forming a status record, which is convenient for tracking and querying.

The system has the function of automatically counting various types of items. The positioning card enters the item number, positioning card number, item type, and item description when entering the warehouse. The information is uploaded to the transmission interface through the card reader base station, and the transmission interface is uploaded to the host. The host analyzes and counts. Calculate the quantity of each type and complete the inventory of the inventory items.

Item outbound statistics can record item number, item type, in-warehousing time, out-of-warehouse time, whereabouts and other information. The item number, item type, in-warehouse time, and out-of-warehouse time are automatically generated by the system at the time of outgoing, and the destination needs customers The choice is made, and the choice of whereabouts is the information entered in advance by the customer.

3.3 System overall design drawings

3.4 System function

Warehousing management: Bind a positioning card to the item. When entering the warehouse, you can enter the item number, positioning card number, item type, item description and other related information. The information will be reported to the host through the base station and displayed in the item information column of the item management.

Item query: Provide multiple query methods, which can query items according to their area, shelf number, item type, item number, location card number, maintenance status, and storage time.

Item positioning: Item positioning provides three positioning methods: item number positioning, item card number positioning and item type positioning. Enter the item number or card number or select the item type and click on the card number bound to the item to be located. Sound and light alarms can be generated. At the same time, the location information displayed on the warehouse map can be based on the location on the map and the sound and light alarm information of the positioning card. It is very convenient to find the located items.

Item maintenance record: There are two indicator lights on the positioning card, which can record the current status of the item according to the status of the indicator lights. There are four states in total: the red light flashes once, the buzzer sounds once, the red light and the street light flash each The buzzer will sound twice twice, the green light will flash three times, the buzzer will sound three times, and the red light will flash four times, and the buzzer will sound four times. The four states can respectively represent the four different states of the item: missing parts, pending maintenance, under maintenance, and maintained.

Item inventory: Item inventory can automatically count various types of items and quantities without manual operation.

Item outbound statistics: Outbound statistics include item number, item type, in-warehouse time, out-warehouse time, destination and other information. It can be inquired according to item number, item type, whereabouts and time.

4. System construction plan

4.1 Hardware composition

Fixed (omni) directional reader, installed and fixed on the warehouse door or warehouse wall, installed one set every 100 meters, used to receive the radio frequency signal emitted by the electronic tag;

The activator is installed on the shelf, and each shelf is equipped with a set of activator, which is used to activate the sound and light search label and remotely write its own code into the electronic label chip. The code is remotely transmitted to the directional reader through a 2.4G label. ;

Optical fiber communication systems, optical transmitters, optical receivers, optical fibers, repeaters, optical fiber connectors, couplers, etc., together form an optical fiber communication system, which is used to transmit the radio frequency signals received by the reader to the monitoring center.

4.2 Precautions for hardware installation

For fixed (full) orientation reader installation, attention should be paid to the installation height (usually 3-4 meters), the waterproof connector (power connector, network connector), and the orientation of the antenna panel;

For the installation of the activator, the antenna installation position of the activator is generally at the middle of the shelf or 1 meter away from the shelf.

The installation height of the activator is generally 2-3 meters, pay attention to the waterproof treatment of the joint;

The installation of optical fiber communication system mainly pays attention to the waterproof of the connector;

[ad_2]