Warehouse management application solutions

[ad_1]

Logistics refers to the movement of material entities in space and time. Accurate logistics refers to the fact that logistics systems rely on information technology with digital networks as the core to realize material visualization and dynamic simulation, accurate prediction, and grasp the flow and flow of materials. This is the basis to realize efficient and reasonable operation methods at each node of logistics. In order to achieve precision and speed, precision logistics must adopt many modern information technologies. “Mobile positioning” is one of the technologies that must be applied in precise logistics, which makes the transportation equipment of logistics in different places transparent and controllable. Generally, the functions of “mobile positioning” required by logistics enterprises include: real-time access to the geographic location, running direction, running speed, and various status information of the monitored vehicle, and it can also report the location information of the vehicle regularly according to the set time interval. Achieve continuous monitoring for 24 hours, and continuous tracking of a vehicle can also be performed on the monitoring screen. Additional functions include: vehicle management, vehicle status, regional vehicle inspection, alarm management, historical record management, driving route analysis, etc. Positioning, monitoring, and commanding and dispatching vehicles and other moving targets can help logistics companies conduct scientific management and reasonable scheduling of logistics vehicles, reduce vehicle idling rates, improve operating efficiency, save fuel, and effectively reduce operating costs.

Inventory control and delivery will bring huge losses to the company. This is not only manifested in the increase in various management costs of the company, but also makes it difficult to guarantee the quality of customer service, and ultimately affects the company’s market competitiveness. Therefore, we have proposed a new RFID-based logistics system solution to solve the problems of precise warehouse management and real-time logistics positioning. Let’s analyze the economic benefits brought to the enterprise by adopting radio frequency identification technology.

The economic benefits of RFID (radio frequency chip)-based warehouse management to enterprises

Problems existing in traditional warehouse management centers

Consumers need high-level services and competitive prices, so it is necessary to set up distribution centers for centralized distribution, which can organize logistics activities more effectively and control logistics costs; centrally store materials and maintain reasonable inventory; improve service quality, Expand sales; prevent unreasonable transportation. In order to accomplish these goals, traditional warehouse management faces the following problems:

(1) Inaccuracy of inventory statistics: Because some barcodes are unreadable or there are some human errors, inventory statistics are often not very accurate, which affects the distribution center to make correct decisions.

(2) Incorrect order filling: Many orders are not filled in correctly, so it is difficult to guarantee that the distribution center can send the correct quantity of the required goods to the correct place every time.

(3) Loss of goods: Loss of goods during transportation is always a problem that plagues the distribution center. Loss is caused by goods stored in the wrong location, goods are stolen and lost, and goods are packaged or shipped incorrectly. According to a survey in the United States, the loss of goods in the retail industry can reach 1.71% of sales.

(4) Inventory of goods: Traditional methods are very inefficient when cleaning up the goods, and in order to know the inventory status of the goods in time, it is necessary to check the goods at any time, which requires a lot of manpower and material resources.

(5) Labor cost: Labor cost has become a serious problem. Statistics show that the proportion of labor cost in the entire supply chain cost has risen to about 30%.

Modern warehouse management needs to be equipped with automated and labor-saving logistics equipment and technology. It should also have a modern logistics management information system and modern management methods. The application of radio frequency chip technology in the warehouse management of distribution centers will bring revolutionary changes. . The wide application of Warehouse Management System based on radio frequency chip technology provides effective technical support for improving the operating efficiency of the distribution center.

The benefits brought by the use of RFID radio frequency chips in the warehouse management system

Traditional warehouse management generally relies on a non-automated paper document-based system to record and track incoming and outgoing goods. The internal management of the warehouse is completely implemented manually. Therefore, the efficiency of warehouse management is extremely low, and the warehouse that can be managed The scale is also very small. With the popularization of computer applications, most of the enterprise warehouse management data materials have begun to use computer data systems for management, but the data is still collected and statistically organized by first recording on paper and then manually inputting it into the computer. This not only causes a lot of waste of human resources, but also due to human factors, the data entry speed is slow and the accuracy rate is low.

With the continuous development of the scale of the enterprise, the number of types of materials managed by the warehouse is increasing, the frequency of in and out of the warehouse has increased sharply, and the warehouse management operations have become very complex and diversified. The traditional manual warehouse operation mode and data collection method have been difficult to meet the warehouse management. The rapid and accurate requirements of the company have seriously affected the efficiency of the operation of the enterprise and become a major obstacle to the development of the enterprise.

Based on Radio Frequency Identification (Radio Frequency Identification, abbreviation)RFID)’S warehouse management system is to introduce RFID technology into the existing warehouse management to automatically collect data from each operation link such as warehouse arrival inspection, warehousing, outgoing, allocation, shifting, inventory counting, etc., to ensure The speed and accuracy of data input in each link of the warehouse management ensure that the company can accurately grasp the real data of the inventory in a timely and accurate manner, and reasonably maintain and control the company’s inventory. Through scientific coding, it is also convenient to manage the batch and shelf life of items. Using the system’s location management function, you can also grasp the current location of all inventory materials in a timely manner, which is conducive to improving the efficiency of warehouse management.

After adopting RFID technology, it will bring the following benefits to enterprises:

(1) Save the cost of manual data collection;

(2) Automated warehouse management operations to improve work efficiency;

(3) Reduce management costs and human errors

(4) More precise control of import, sale and inventory;

(5) Enhance partnerships;

(6) Quickly respond to customer needs and expand product sales.

According to the analysis of Accenture Consulting, a member of the Automatic Identification Center, the use of radio frequency chip technology can:

* Reduce inventory by 10~30%;

* Increase the utilization of inventory space by 20%;

* Reduce labor costs by 10-40%;

* Speed up picking and delivery by 10%;

* Reduce the loss caused by theft and improper storage by 50%;

* Increase sales by 2~10%;

* The transportation cost is reduced by 2 to 13%.

* Shipment accuracy reaches 95% (pallet transportation companies can exceed 99.9% accuracy);

* Billable returns are reduced by 80%;

RFID-based warehouse management system

System design principles

This program strictly follows the technical specifications involved in the project. Maximize the use of the most advanced technology of existing computers. Follow the principles of real-time, integrity, stability, advancement and scalability, and establish an economically reasonable and resource-optimized system design plan.

(1) Real-time: This system adopts the most advanced high-speed wireless network technology to make all the planning, operation, scheduling, control and management of the warehouse real-time, greatly improving the efficiency of existing equipment and personnel in the warehouse, and realizing logistics management The greatest benefit.

(2) Integrity: This system involves wireless handheld devices, wireless receiving devices, database front-end and back-end database servers. Although they are physically separated from each other, they all have their own system support. In order to enable the various parts to work in a unified and coordinated manner, the overall consistency between them must be ensured in the design.

(3) Stability: This system is a production information system for warehouse management and field operations. For this reason, when designing the system, an error analysis module is added to verify all possible errors. In addition, the efficiency and stability of the system are optimized in the design, so that the system can ensure the stability while ensuring the speed. Through the above measures, when the system is in operation, when there are human errors or some random errors in the system, it does not affect its operation.

(4) Advancement: This system is an intelligent system integrating computer software and hardware technology, wireless network technology, internet network technology, bar code automatic identification technology and database technology. The electronic commerce subsystem of the system adopts the most popular computer three-tier structure system in the industry, adopts Java language, and provides XML interface.

(5) Scalability and maintainability: According to the principles of software engineering, system maintenance occupies the largest proportion in the entire software life cycle. Therefore, improving the scalability and maintainability of the system is an indispensable means to improve the performance of this system. This system adopts a structured and modular structure, and a certain module can be modified and new functions can be added as needed to make it have good maintainability. The system also reserves interfaces with other subsystems, which makes the system have better scalability.

Main functions of the system

The warehouse management system based on RFID technology has the following basic functions:

① Update various information automatically and accurately;

When the goods are in and out of the warehouse and need to be updated, you only need to fix the corresponding data through the handheld PDA to complete the update of the warehouse; or through the query database, find the corresponding model of the goods and update the data.

② Query and track cargo information;

Log in to the system software terminal, search for the specific information of the goods to be queried, and transfer the searched information to the PDA, so that the identification plate can be easily found and the goods can be tracked;

③ Cargo position inquiry, dynamic allocation of goods position, random storage, so as to maximize the use of storage space;

Log in to the system software terminal, query the cargo location information, and realize the dynamic allocation of goods according to the cargo location storage space information, so as to maximize the use of storage space

④ Realize the dynamic and comprehensive allocation of human and material resources;

In the warehouse management process, not only the support of the system terminal database is required, but also the manual operation with a PDA is required to realize the dynamic and comprehensive allocation of human and material resources.

⑤ Comprehensive inventory function of the warehouse system;

When the warehouse system inventory is carried out, the passive tags on the identification plates can be read through the handheld PDA, the statistics of the goods, and the data are returned to the system terminal for processing and inventory

⑥ Random inspection and inventory within the warehouse;

Log in to the system terminal, then search for a certain type of goods, obtain relevant information about the goods, and transfer the data to the handheld PDA. The staff can find the corresponding cargo location according to the transmitted data, and complete the random inspection and inventory work within the warehouse;

⑦ Real-time statistical reports, summarizing all kinds of information.

The warehouse identification plate is read through the handheld PDA, the information is obtained, and the information is transmitted to the system terminal, which can realize the system summary of the warehouse and make statistical reports.

Warehouse management

Warehouse Management Object

The main body of warehouse management is the warehouse administrator, and its management objects include:

(1) Inventory: Items kept in the warehouse, which is the fundamental object of warehouse management; limited to the current system is not suitable for managing every small single item, so the unit that uses RFID to manage items is the entire category of items (Including large items).

(2) Storage location: the area in the warehouse that is used to store inventory items and does not overlap each other in space. Generally, one storage location can store multiple inventory; it can also occupy several storage locations for a larger inventory. .

(3) Warehouse management equipment: equipment used for warehouse management, such as forklifts, trolleys, etc.; these equipment need to be reasonably scheduled and real-time positioned in large, busy warehouses to improve equipment utilization.

Warehouse management tasks

The main tasks of warehouse management are as follows:

(1) Warehousing (incoming inspection)

(2) Delivery (selection)

(3) Move warehouse (replenishment)

(4) Disk library

(5) Generate various inventory reports according to needs

System overall design

The basic idea

When the items are put into the warehouse, they are classified according to the specifications, put into the corresponding storage area, and an identification plate is installed for each storage area, and each identification plate is affixed with an electronic label, which is called an identification label . And give each identification plate number, the label stores the id number that can uniquely identify the shelf, and the staff can hold the PDA to read the id number on the label, and then call the back-end system database to obtain the stored information. The information includes: items Type, name, model, unit, unit price, production date, shelf life, performance, etc.;

When goods need to be moved to the warehouse, log in to the system software terminal, and the system sends the warehouse instruction to the PDA. The warehouse staff finds the designated goods location, takes out the designated quantity of goods from the warehouse, and transports the goods to the destination warehouse, and the goods are sent in Warehouse location, modify the shelf label content; send back to the on-site system the operation information of the warehouse.

The PDA in the operator’s hand scans the inventory identification board, and sends the scanned data to the terminal computer in real time, and the monitoring personnel perform inventory statistics and make statistical reports.

When performing warehouse management operations, read the tag number to determine whether the current job location is correct. In addition, as long as the id number of a certain shelf is entered, the relevant information of the id can be retrieved from the online database, so as to realize the material storage function and realize the online browsing and query.

System Components

The warehouse management information system consists of three parts:

(1) Warehouse management center subsystem: Responsible for the centralized management and maintenance of the warehouse management database, responsible for the formulation of purchase plans, outbound plans and ordering; printing and generating various management reports.

(2) Warehouse management on-site subsystem: issue warehousing tags, perform real-time inventory management (location management), and issue warehouse management instructions through the wireless network.

(3) Warehouse management execution subsystem: complete specific operations such as storage, storage, transfer, and inventory, and return to the actual status of execution.

Work flow

Making and installing location labels

Unless the location is adjusted or the label is damaged, generally the location label only needs to be made and installed once. The operation steps are as follows:

Code the location first

Use the RFID reader to write information such as the location code into the electronic tag;

Use a label printer to print location coded text and bar code information on paper labels;

Paste the paper label on the electronic label to generate the location label;

Install the location label on the location. It is required to be installed firmly to prevent it from falling off; and the labels are required to be installed on the supporting beam directly below the storage location as much as possible.

Warehousing operation process

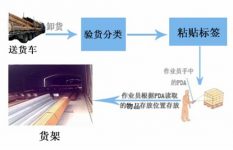

The warehousing operation process is shown in the figure below:

1) Receipt inspection

Key inspection:

Whether the delivery note is consistent with the purchase order;

Whether the arrival of the goods is consistent with the delivery note;

If it does not match, refuse to accept.

2) Make and paste labels

The specific method is as follows:

First classify the oil pipes, steel pipes and other goods to be stored in accordance with the specifications;

The goods are allocated and managed by category, and a sign is installed in each cargo area to identify the information of the goods;

Then paste a passive electronic label on each identification plate to number the identification plate. Each label stores an ID number that can uniquely identify the identification plate. The ID number corresponds to the relevant information of the stored goods in the database. The information includes: The type, name, model, unit, unit price, production date, shelf life, performance, etc. of the tubing, and number each identification plate;

3) The operator transports the goods to the designated location, checks the location and sends the goods into the location (if necessary, modify the cargo number and quantity information recorded in the location label);

4) The wireless data terminal sends the actual status of the storage to the on-site computer to update the inventory database in time.

Outbound workflow

See the figure below for the outbound operation process:

1) Log in to the system terminal and search for outbound cargo information;

2) The system computer sends out the library instruction;

3) After the operator’s PDA receives the data, follow the instructions of the data terminal and arrive at the designated sign;

4) Take out the specified number of oil pipes from the warehouse to complete the outbound task;

5) Rewrite the content of the identification label;

6) Send back the completed outbound operation information to the system computer;

7) Update the central database.

Move library operation process

The flow chart of moving the library is as follows:

1) According to needs, the on-site computer compiles library transfer instructions and downloads them to the data terminal;

2) The operator arrives at the designated storage location according to the prompt of the data terminal;

3) Take out the specified quantity of goods from the storage location and rewrite the content of the storage location label;

4) Transport the goods to the destination location, send the goods to the location, modify the location label content;

5) Send back the operation information of the library to the on-site computer;

6) Update the central database.

Inventory work flow

The inventory operation flow chart is as follows:

The inventory operation process is as follows: you can use the PDA in the hands of the operator to scan the inventory identification plate, and the scanned data can be sent to the terminal computer in real time, and the monitoring personnel can perform inventory statistics and make statistical reports.

Data transmission method

No matter what kind of operations such as storage in, out of storage, inventory, transfer, etc., warehouse administrators need to transfer data between the handheld PDA and the system database backend. The transmission method is as follows:

Read the electronic tag data through a handheld PDA. After receiving the signal, the PDA sends the data to the data receiver through GPRS. The receiver is connected to the system terminal through the 485/232 interface, and the received signal is transmitted to the database to complete the corresponding update operation of the data .

[ad_2]