Warehouse Management of Carton Factory Based on RFID Technology

[ad_1]

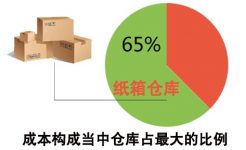

With the increasingly fierce market competition, the current carton industry is facing a very difficult business environment. The small business volume and the instability of raw material prices are prominent, which brings great difficulties to the operation of enterprises. Raw materials, the most important factor in the cost of cartons, determine the production cost of the product. Therefore, whether the warehouse management of the cartons factory is in place determines the lifeblood of the company’s development. Tianjin Little Bee believes that doing a good job in the warehouse management of the carton factory is of great significance to better improve the production efficiency of the carton and improve the product quality of the carton.

Warehouse management in a modern carton factory is a science, and it also involves applied technology science. A carton factory of a certain scale can use the information management system to implement scientific and fast management of the storage, so as to make full use of resources, reduce the cost of production and operation, maximize the economic benefits of the enterprise and protect the products. The warehouse management of a modern carton factory should be a specific process of production planning, production organization, production control, and production coordination. The specific warehouse management should include the sorting and management of warehouses, the planned control of material storage, the management of warehousing processes, the management of warehousing operations, The custody and management of materials, the safety management of materials, etc. It can be said that the warehouse management of a modern carton factory is an important part of production and operation, as well as an important link in production cost control.

How to effectively combine the warehouse management of the carton factory with the production process?

It can be said that in the era of the Internet of Things, information management is not just as simple as recording and transmission. This also involves the efficiency of information recording and transmission, as well as the establishment of a complete set of systems for the management of KPI indicators and management models.Tianjin Little Bee believes: PassedRFIDRadio frequency technology can effectively achieve the above goals.

Radio Frequency Identification, RFID (Radio Frequency Identification) technology, also known as radio frequency identification, is a communication technology that can identify specific targets and read and write related data through radio signals without the need to establish mechanical or optical contact between the identification system and specific targets . Compared with the traditional bar code information recording mode, RFID has a faster reading speed, larger information capacity, and better environmental adaptability.

How to apply RFID technology to warehouse management in carton factory?

1. Hardware deployment and process management

In the early stage, the raw materials and finished products in the warehouse need to be effectively divided into warehouse areas, and RFID electronic tags should be installed in the corresponding storage area to locate the cargo space, and then paste the electronic labels on the pallets of the raw materials and finished products. The reader enters the information and transmits it to the warehouse management system of the carton factory via the wireless network.

When finished products and raw materials are in and out of the warehouse, a fixed reader installed at the door of the warehouse can instantly read the cargo information for recording. At the same time, when the goods are removed from the shelves and put on the shelves, the staff can simultaneously record the information of the goods on the shelves. Because RFID technology can almost synchronously record the operation information in the warehouse management of the carton factory, it can be connected with the enterprise’s ERP system at the same time, and control the company’s comprehensive information in real time, providing a basis for the decision-making of enterprise managers.

2. The effect of warehouse management in the carton factory after the adoption of RFID technology is improved

1. Reasonably allocate warehousing personnel to reduce management costs

The deployment of personnel in a carton factory is one of the factors contributing to storage costs. Reasonably setting up management institutions and personnel according to the factory’s conditions to reduce levels and contradictions is of great significance for improving the efficiency and quality of the factory’s warehousing and reducing the cost of warehousing and logistics. RFID technology can effectively record the efficiency of manual operations in the warehouse, effectively record performance indicators, and provide a basis for managers to control labor costs.

2. Strengthen warehouse management and reduce production costs

Whether the warehouse management of the carton factory is in place is largely related to the storage cost. Because some factories lack detailed management methods for the in and out of raw materials, blindly stock raw materials, which not only affects the flexible turnover of funds, but also increases the storage cost. The use of RFID technology can reflect important KPI indicators such as inventory information in real time, prevent interest, prevent material supply shortages from affecting normal production, and ensure the smooth flow of production logistics channels.

3. Realize a reasonable warehousing plan to reduce production costs

Relying on the powerful real-time synchronization technology of RFID, companies can completely realize the reasonable preparation of storage plans and reduce production costs.

Tianjin Little Bee believes that the storage role and function of modern carton factories have far exceeded the original meaningful inventory, and RFID technology has given it a broader, richer and more profound connotation. We firmly believe that the future Internet of Things technology will completely change our lives, and RFID will be applied to various industries on a large scale.

[ad_2]