Vehicle Intelligent Weighing Management System

[ad_1]

I. Overview

In order to effectively manage the transportation and handling of goods, move to a more structured, standardized and scientific way, so as to improve the management level and reduce the cost, the comprehensive management department of each incoming and outgoing goods yard/station and the transfer disposal center shall be established.

Establish a “vehicle intelligent weighing system”, through the establishment of a data center, the cargo transfer and disposal center will be connected with its respective departments, including the cargo yard/station and transfer station, to complete the computer management system for the cargo transfer and disposal.

The data generated by various departments can be shared, and the analysis and statistics of daily data reports can be carried out.

AWS (Auto Weighing System) Vehicle Intelligent Weighing Management System is a combination of technologies in automatic weighing systems, access control systems, and parking lot automatic control systems with remote RFID radio frequency automatic identification systems.

Integrated intelligent integrated management system. The system uses electronic truck scales, long-distance RFID radio frequency equipment, barriers, signal lights, etc. to integrate into an intelligent system. It can automatically record the ID, weight, time, unit and other information of the incoming and outgoing vehicles, and write them directly into the host database. The host can transmit data to the monitoring computer in real time, and the monitoring computer can call the data in the host database. The system can adjust the working mode according to different requirements, and interface with different types of electronic truck scales.

The use of radio frequency identification technology coupled with electronic weighing instruments has greatly improved its accuracy, function and automation level, making the intelligent weighing system gradually replace the traditional mechanical weighing instruments to become a fixed trend.

The recognition rate is high, the measurement value is accurate, the measurement speed is fast, it is highly automated, and it is easy to use;

Simple structure, convenient debugging and installation, wide weighing range and strong adaptability;

It can transmit information over long distances, and can be remotely controlled and group controlled, so that the system can be truly automated and intelligent. It can also be networked with a computer to automatically analyze, calculate, and print data records and reports.

1. System coverage

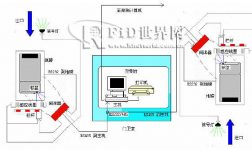

2. System application deployment structure diagram

3. System structure

The intelligent vehicle weighing system mainly includes the automatic weighing system of truck scale, the intelligent management system of vehicle entry and exit, and the computer management system of the disposal center. The automatic weighing system for truck scales and the intelligent management system for vehicle entry and exit are used in freight yards/stations and transfer stations. And the export data forwarding program completes the communication link and data transmission tasks between the station and the transfer station management center (disposal center computer management system).

2. System function

1. Auto weighing system for truck scale

Possess all the functions of GM truck scale;

It has the function of weighing and measuring under unattended conditions, and automatically realizes weighing and measuring, data recording and result printing for vehicles entering the truck scale;

Manual and automatic measurement and interchange operation at any time, and carry out weighing measurement, data recording and result printing;

While weighing the vehicles entering the truck scale, it can also enter the number, license plate, unit, driver and other information of the entering vehicle;

Report generation and printing.

2. Vehicle entry and exit intelligent management system

A. Access control system

Automatic long-distance recognition and confirmation of ID cards for vehicles entering and leaving stations

Access control

Weighing and data entry

Data processing and display

Weighing measurement and billing calculation

Result statistics and report printing

Bill and report printing

Inspection and review

B. Financial card issuing system

Follow the work procedures to issue “ID fixed card” and “ID stored value card” (registration, file creation, inquiry, review, review, invalidation, cancellation)

Management of ID card loss and reissuance

Perform statistics and overall accounting

Perform verification and error correction

C. Monitoring work system

Real-time monitoring record of passing vehicles

Real-time monitoring record of cargo type and status

Fire monitoring record

Monitoring records of key work locations

Important matters record

Reminder of remaining issues

On-duty record and shift record

D. Background data processing

Process the incoming and outgoing conditions of vehicles and the weighing data of truck scales

Data statistical analysis function

E. ID card management

ID cards are divided into fixed cards and stored-value cards, all of which can issue, manage and cancel ID cards

With review authority function

Each workstation can inspect and supervise the use of ID cards, and can query and manage online

3. Computer Management System of Disposal Center

A. Unit information management

Unit information input, query, modification, printing

B. Vehicle management

Entry, query, modification, and printing of basic vehicle information

C. Cargo management

Cargo information entry, query, modification, printing, statistics

D. ID card management

ID card issuance, ID card loss report, ID card recharge, ID card management

E. Vehicle entry and exit registration management

Vehicle access information registration, query, modification, printing

F. Statistics and print reports

Cargo handling, stored-value card usage, measurement information, vehicle management information statistics, vehicle access information, unit information statistics

G. System function management

User management, authority management, user log, change password, log out of the system, change system login

Three, technical indicators and parameters

1. Software environment indicators

Database system: SQL SERVER

Working mode: CLIENT/SERVER (C/S)

Operating system: WINDOWS

2. Database performance indicators

1) Security

The intelligent vehicle weighing system can separate application software and data, and on the basis of realizing data sharing, ensure the integrity and safety of data;

Under the guarantee of the database system’s own security, all levels of sub-systems are assigned corresponding operating permissions, and permission levels are set to ensure the security and confidentiality of the database;

Strengthen the security of operating systems, computer systems and network systems.

2) Reliability

All levels of hardware systems adopt dual-system hot backup and data disk array backup;

The system fully considers the impact of emergencies and various failures on the system. Corresponding preventive and rescue measures should be taken in the application system, and data recovery and recovery functions should be adopted.

3) Response time

The main server and network equipment of the vehicle intelligent weighing system run around the clock;

All data is backed up by month, and the whole year is backed up for data storage management.

3. System development methods and development principles

The system is designed and developed using the Client/Server model, and a central database is set up on the server to store the information and data shared (uploaded) by the subordinate workstations.Data transmission adopts dial-up Internet, real

Now data transmission. The vehicle intelligent weighing system is developed using a combination of life cycle method and prototype method. During development, the prototype method can be used to quickly generate a system model for users to intuitively understand the structure, function and interface style of the new system. Users continue to put forward new requirements based on the prototype; at the same time, use the life cycle method to define each stage of system development . Summarize and analyze the new requirements of users, and continuously improve the intelligent vehicle weighing system. Therefore, the system is developed using a combination of life cycle method and prototype method in the development process, and the design is carried out from the top to the bottom, and the development is carried out from the bottom to the top.

The system abides by the following principles during the development process:

1. Consider the interface between the vehicle’s intelligent weighing system and the current hardware system;

2. Monitor import and export vehicles;

3. Standardization and standardization of input data to ensure the accuracy of data input items;

4. Ensure the security of the data center, and ensure the security of the data through encryption technology;

5. It has the function of initializing basic information;

6. Friendly interface and convenient operation.

4. System technical features

Unified maintenance and update of system data

The data dictionary of the vehicle intelligent weighing system is maintained uniformly by the system administrator. It can ensure the accuracy and completeness of the information of the vehicle’s intelligent weighing system.

Data entry flexibility

The system makes full use of a large number of basic data relationship tables to minimize the input data.

Advancement of software structure

The system software architecture is designed according to the current popular distributed computing technology. It adopts a three-tier architecture of Client/Server (client/server) structure, which is divided into three levels: application processing layer, business logic processing layer, and data object management layer. The transaction submission is distributed and interacted by the business logic layer, making full use of the advantages of distributed computing technology, which can greatly reduce the pressure of the fat client’s business data processing load, thereby realizing the comprehensive sharing of network resources. The system software is logically divided into three processing levels from bottom to top:

Application processing layer: Provide user operation interface.

Business logic layer: The communication between the client and the server is completed through the COM (Microsoft Component Model) mechanism.

Data object management layer: complete the submission and processing services of all transactions in the business logic layer.

Database technology advancement: The system uses SQL SERVER as the back-end database, and makes full use of SQL SERVER’s network characteristics: concurrency, snapshots, easy operation and other advanced technologies to ensure timely, reliable and stable operation of system information.

System security

The system adopts a three-level security control mechanism of database system, operating system, and application system, encrypts and stores the business password of the system, and maps the terminal to each terminal via IP, ensuring the safety and reliability of the system.

Database installation flexibility, data backup management convenience

Provide basic data dictionary, one-time installation and configuration. The application software provides the backup of the business data and basic data of the database.

Advancement of software and hardware technology

Adopt advanced computer network and database technology and advanced radio frequency card identification technology to manage and track incoming and outgoing vehicles.

5. Operation and safety management

System operation and safety management are factors that must be considered in the process of system realization. It has been fully considered in this system. The first is the overall network security management. The operating system adopts the Windows Server operating system with strong security management performance, and anti-virus software is installed. At the same time, detailed permissions are set to the system to prevent hackers from intruding.

Four, system software introduction

1. Main interface

The main interface is divided into six parts: the menu bar, the function key bar, the current data bar, the selection bar, the data table bar, and the AWS information bar.

When the system is running normally, the current data column displays the information read in from the reader, and the complete weighing information is written into the data table at the same time.

The data table shows the vehicle information read from the last day-end processing to the present. The sorting category and the sorting method determine the order of the data in the data table.

The selection bar displays the working mode required by the operator, such as selecting the current working reader in the “Communicator”.

2. Menu bar

The menu bar includes file, view, monitor, manage, query, print, set, and help.

1) Monitoring

The monitoring drop-down menu includes start, stop, connect, and close the connection.

“Start”: Start monitoring import and export vehicles, and see the received data information in the current data column and data table column in real time.

“Stop”: Stop monitoring import and export vehicles; the reader remains in monitoring status.

“Connect”: Confirm that the remote monitoring computer has been running the monitoring program, click “Connect”, the host will establish a connection with the remote monitoring computer, and the remote monitoring computer can receive weighing data information in real time.

“Close connection”: Disconnect the connection with the monitoring computer.

2) Management

Management includes operator management, area management, material management, destination management, information card management, and day-end management.

3) Query

Historical data query.

4) Print

The printed list is arranged by material classification. Each material starts with the material name and ends with the net weight subtotal; at the end of the table, the total number of vehicle in and out records and the total net weight are listed. The table shows the information obtained by the reader after the current vehicle enters the electronic truck scale.

. Current Data Sheet

When the current data in the main interface meets the management requirements, the system runs normally, and the current data is automatically added to the data table column;

When the user uses the temporary card, the information does not meet the release conditions. At this time, the system sends a signal to the operator, and the “current status” in the selection bar of the main interface appears red. The vehicle information that the operator must enter. After completion, the “Add” button in the selection bar is lit, click “Add”, the temporary card information enters the data bar, the reader commands the railing to lift, and the weighing process is completed. The column displays vehicle entry and exit information according to the selected sorting category and sorting method.

4. Data table column

Data table in the main interface

Regardless of whether an empty vehicle enters or a full vehicle enters, the AWS system always settles with a positive number in the net weight column. For vehicles that need to be fully driven out after entering a full vehicle, in order to obtain an accurate net weight of materials, they must first be driven out with an empty vehicle through the scale, and after the empty vehicle has been driven in by the scale before being able to load the vehicle through the scale and leave the factory.

Five, system hardware equipment

The main hardware of the system includes: host, RFID reader S1501 (or S1500, S1503, S1513), electronic label card S1255, S1257 (or S1455), electronic truck scale, signal lamp, railing machine, ground induction coil, RS232/485 converter.

1. Reader

The reader communicates with the host through the RS485 serial port. Each reader can monitor the status changes of external control switches or ground sensing coils by detecting the status of the parallel input port; control the operation of signal lights and barriers through the parallel output interface; the host communicates with the electronic truck scale through RS232. Multiple sets of readers can be connected to one host to work. In this case, the reader can form an RS485 multipoint network with the host through the RS485 interface.

The built-in management program of the reading device can automatically complete the object recognition function offline, and the built-in database can store a large amount of electronic label data.

Features:

Free of manual identification;

Serial communication

High-speed reading;

Small size and compact design.

Work normally in harsh environments such as rain, snow, wind, sand, corrosion, etc.

Product technical characteristics:

The working frequency is 2.45GHz, with a circular polarity information magnetic field;

6m-15m reading distance, moving objects can be detected within 15m;

Software setting reading distance/channel (100 optional channels);

3-color luminous tube and buzzer;

User programmable;

Flash EEPROM database;

DTMF and LED interface;

RS232 and 2/4 wire RS485;

3 parallel input, 2 parallel output;

Relay and protective switch;

24V or 12V working voltage;

-20 degrees to +85 degrees work normally.

2. Label card

Use TagMaster S1255, S1455 electronic tags.

Label size: 3mm thick, 8.5cmX5.5cm;

Microwave communication, permanent and unique 32-bit factory identification number;

Reading area: any distance from the maximum value to zero can be read correctly;

Writing area: Not affected by non-metallic shielding, and can be installed on a metal surface;

Communication: Working in the frequency range of 2.435-2.465 GHz, when the tag is set to random mode, the reader can read multiple tags at the same time;

Operating temperature: -20 degrees to +85 degrees;

Service life: more than 6 years.

Adapt to the environment: rain, snow, fog, dust, oil, chemical corrosion, wind and sand, vibration, shock, etc.

[ad_2]