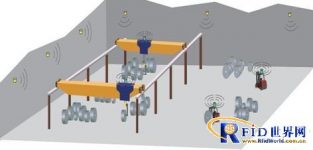

Steel warehousing positioning and management

[ad_1]

Outline requirements:

Modern steel logistics is increasingly showing development trends such as informatization, networking, automation, intelligence, and standardization. The accurate positioning of informatization needs is the key to the success of informatization of logistics enterprises. Dunn’s precise steel warehouse positioning management program is fully automated-crane automation, grabbing automation, and stacking automation. Instead of manual operation, the work efficiency and production safety of the steel warehouse are comprehensively improved.

1. Precise positioning of cranes and spreaders

Two sets of LPR-1DHP sensors are installed on the traveling vehicle that needs to be positioned to achieve a positioning accuracy of 1CM. One set is installed at the two ends of the traveling direction to measure the distance traveled by the traveling vehicle; the other set is installed on two sets of the spreader in the traveling direction. End, used to measure the distance traveled by the spreader on the driving vehicle. Using the 2 sets at the same time, you can measure the precise two-dimensional position of the crane spreader, so as to accurately record the storage location of the steel, which is convenient for storage management and next extraction.

Features:

• Using high-frequency radio measurement technology, the system is maintenance-free;

• Independent frequency band, does not interfere with on-site WIFI and other wireless equipment;

• All imported products can be used in harsh environments;

• Rugged and durable, high protection level;

2. Positioning of steel warehouse cargo

In the positioning unit, 6 radar transceivers can be installed to achieve 2D positioning. Installing a base station and two antennas on the forklift can determine the 2D position and heading angle of the forklift. As long as six radar transceivers are installed on a given light pole, wall or other infrastructure construction, it can cover an area of 300X300 meters. For larger areas, more radar transceivers can be cascaded. So as to realize the precise position of the goods and the spreader, automatic lifting.

Features:

• Non-contact measurement via radio waves;

• Not affected by indoor operation, outdoor operation, pollution, and weather;

• There are no restrictions on the system requirements, the installation is relatively simple, and it can be modified before continuing to use;

• Suitable for all types of vehicles and cranes;

[ad_2]