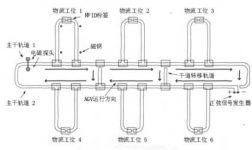

AGV trolley track guidance management

[ad_1]

With the ever-increasing manufacturing level and customer demand, logistics systems in various industries are facing many challenges. How to improve the turnover efficiency of the logistics system and reduce labor costs? How to improve the technology and accuracy of logistics and transportation? How to quickly complete the heavy Goods picking function and so on. The business decision-making level of enterprises pays more and more attention to the overall operation efficiency of the entire logistics system. In order to solve these problems, the logistics system needs to be optimized from a system perspective, and advanced logistics scheduling and optimization algorithms are needed to improve the overall logistics efficiency.

Logistics scheduling and optimization algorithms are the core of the entire intelligent warehousing system, involving inherent warehousing models, workflows, automation equipment, and operation management software systems. Through generalized models and personalized customized interface systems, mobile robots can be used as interfaces. Effectively connect logistics personnel, automation equipment, and logistics management software to realize the overall logistics scheduling and optimization system.

The RFID AGV trolley reader guides the node selection of the AGV trolley, so that the AGV trolley is more intelligent and automated.

Product advantages:

1. Compact AGV trolley reader;

2. IP65 industrial design;

3. Impact resistance, anti-corrosion, suitable for harsh working environment;

4. Support RS485 bus, convenient networking;

[ad_2]