Application scheme of RFID management system for warehouse materials in and out

[ad_1]

1. Project background

At present, market competition is becoming increasingly fierce, and improving production efficiency and reducing operating costs are of vital importance to enterprises. Warehousing logistics management is widely used in various industries, designing and establishing a complete set of warehousing management processes, improving warehousing turnover efficiency, reducing the occupation of operating funds, turning frozen assets into cash, reducing the cost caused by warehousing elimination, and improving the company An important part of production efficiency.

2. Project target design

Warehouse inbound and outbound eliminates the tedious work of scanning piece by piece, and the speed has been greatly improved.

The bar code label on the cargo space is difficult to visualize in the warehouse, and the forklift driver can easily put the cargo space in the wrong place.Via the wireless PC on the forklift andReaderIt can ensure that the target cargo position on the shelf is correct.

The forklift interacts with the host through a wireless PC, and can grasp the position and status of each forklift in real time. The forklift scheduling can be more flexible and the utilization rate of the forklift can be maximized.

Forklift drivers can receive inbound and outbound instructions and shortest path guidance through the wireless PC, which can put the goods on the shelves and pick them out of the warehouse faster and more accurately, which can shorten the forklift driver’s working time in the warehouse.

When the goods cannot be placed on the target location due to various reasons, the forklift driver can place the goods in other locations, and by reading the location tag association and wireless PC interaction with the host, the real-time accuracy of inventory information can be ensured. Avoid the original cumbersome process when the target cargo space cannot be placed, and because the forklift driver is busy with no record and the target cargo space is not recorded, the inventory is inaccurate, which may lead to major losses due to shipping errors!

When the storage of goods is not specified by the system, but the forklift crashes to determine the storage location of the goods, the real-time storage information can be submitted to the host system through the RFID forklift, which is compared with the manual record of the traditional scheme and then entered into the computer scheme. The real-time performance and accuracy have been greatly improved, and the efficiency has also been greatly improved.

In traditional warehouse inventory, each box of goods needs to be scanned at close range. The use of RFID technology will greatly simplify the above procedures. The results of the inventory can be transmitted to the system through the wireless network for recording, eliminating the need for manual entry.

3. Program overview

This program is tailored for customers by Shanghai Fuen through analysis of the needs of the company. It integrates RFID technology, network technology, computer technology, database technology, and wireless communication technology. Combining the actual needs of the company and Fuen’s rich experience and unique technology. We propose the following RFID system solutions.

4 system advantages

Labor can be reduced by 20-30%;

99% of warehouse products are visualized, reducing the risk of missing goods;

Improved supply chain management will reduce work service time by 20-25%;

Improve the accuracy and reliability of storage information;

Efficient and accurate data collection provides operational efficiency;

Automatic collection of incoming and outgoing data to reduce human error;

Reduce enterprise warehousing logistics costs.

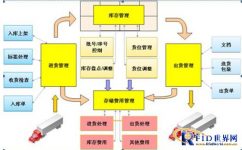

5 System operation process

6. Major equipment deployment

No matter what kind of operations such as storage in, out of storage, inventory, transfer, etc., warehouse administrators need to transfer data between the handheld PDA and the system database backend. The transmission method is as follows:

Read via handheld PDAelectronic labelAfter receiving the signal, the PDA sends the data to the data receiver via GPRS. The receiver is connected to the system terminal through the 485/232 interface, and the received signal is transmitted to the database to complete the corresponding update operation of the data.

typical application

IC card chain recharge consumption at gas stations;

IC card management of government functional departments (driver, motor vehicle, operation certificate, tour guide certificate, construction industry employment certificate, service industry health certificate, family planning, individual business, technical supervision, industry qualification, urban management, etc.);

All-in-one card application fields (campus, enterprises and institutions, real estate communities, shopping malls, buses, urban citizens all-in-one cards, etc.)

Mobile police application, administrative law enforcement, quality inspection, urban management

Logistics distribution (postal, takeaway, telephone order and online order delivery system, etc.)

Water, electricity, petrochemical, gas inspection, meter reading

Fixed asset management

Mobile consumption, sales and anti-crossing goods management

Patrol/patrol inspection, outside point maintenance;

Mobile toll management of urban roadside parking lots;

Membership chain consumption;

Student physical test management, child vaccination IC card management, and exhibition audience IC card data collection;

Tobacco monopoly management, tobacco logistics management, tobacco leaf purchase management;

Card ticket management, e-ticket management

Manufacturing execution, product tracking and tracing

Army Ordnance Material Management

Retail chain organization management (counters, sales

Mobile sales management, anti-crossing goods management

[ad_2]